Is plastic fibre as good as glass fibre optic cabling in terms of performance or are there differences to consider?

A: Plastic fibre has a much tighter bend radius than glass fibres – great for getting decent bandwidth into tight spaces. Plastic is strong. This added strength means you can be less careful during installation without cracking or breaking plastic fibres. It also means the fibres can withstand serious vibration.

But coupled with its strengths are some weaknesses. The greatest of these is a dislike for hot environments. Anything over 85 degrees C may destroy a plastic fibre run. And despite its greater strength, when you think glass vs plastic you do need to bear in mind that when located in a stable location, glass will simply last longer than plastic fibre can.

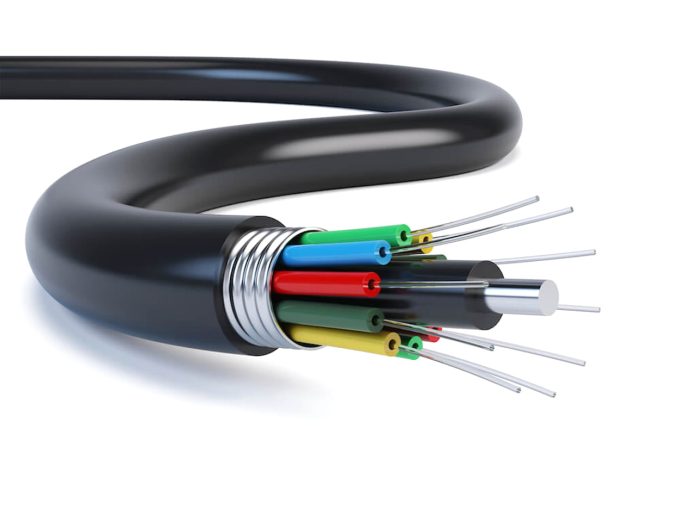

Plastic also has less bandwidth and suffers greater losses, the latter resulting in reduced performance over the big distances where glass fibre really shines. When we say greater losses, we mean much greater – at 650nm plastic fibre has an attenuation of 150dB per kilometre, while silica glass fibres lose just 5dB per kilometre (100/120 diameter pipes at 20Hz). Even awesome lab grade plastics are still around 50dB per kilometre in the loss department.

The problem with plastic fibre when it comes to outright performance is the carbon-hydrogen and carbon-oxygen bonds that hold its atoms together. These absorb large amounts of visible and near infrared light and have a major impact on light loss characteristics. Counterbalancing these negatives is the fact plastic fibre can be blown into place with pneumatics, which is awesome and cost effective in terms of bandwidth.

Generally, there are sites of a size that are perfect for plastic fibre – these sites will be big but not airport perimeter-sized, with many cameras requiring solid bandwidth and with some restrictions on budget.

#sen.news