What are the strengths and weaknesses of thermal surveillance cameras – are they a viable solution for perimeter security applications?

A: Thermal cameras can detect warm objects day and night, regardless of weather and tree cover, at great distances – from several hundred to thousands of metres.

The latest thermal cameras can penetrate fog, smoke and mist, as well as darkness. They are compact and comparatively lightweight – especially when required scene depths are moderate – have modest power consumption and the ability to function on power up. Like most passive sensing devices, mean time between failure is lengthy.

The sorts of applications that best suit thermal cameras have a security team, have fast contract patrol response to off-site monitoring, use the cameras the drive alarm inputs, or simply seek to keep an eye on changing threats to high security perimeters – in real time or retrospectively.

Thermal makes for a massive extension of perimeter detection capability and for really big sites, like mines, solar and traditional power generation plants, and industrial facilities with line of sight along perimeters, thermal is a great solution. In mentioning line of sight, it’s worth pointing out this applies to metal objects or buildings – thermal cameras can see deep into heath, bushland and tree cover either on the sterile or public side of a secure perimeter.

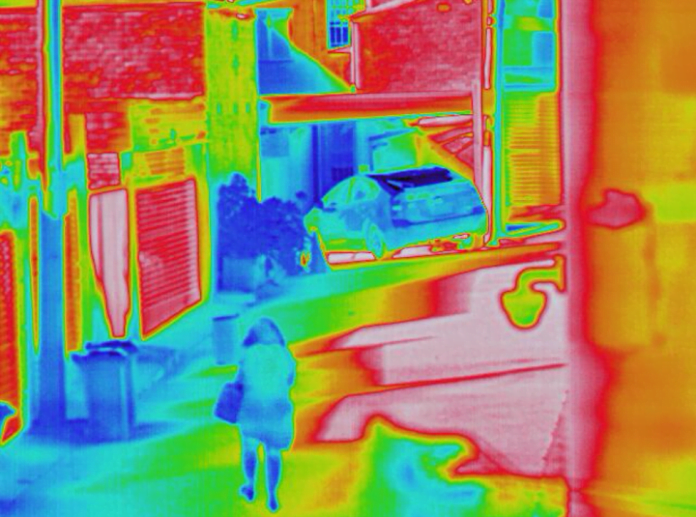

The key weakness of thermal cameras is that this imagery does not provide optical detection, including plates and faces, though some cameras are far better than others in this regard – especially those with higher resolution sensors – and many thermal cameras incorporate thermal and optical sensors. There are some limitations with respect to fog and rain with thermals – moisture can attenuate signal. Another critical aspect of thermal imaging is thermal sensitivity (NEdT/NETD) – are you blind or can you see?

The heart of any modern thermal imaging camera is the un-cooled microbolometer – essentially that’s a bolometer fitted as an image sensor. This sensor is responsive to IRE in the 8-13um range. When IRE reaches the microbolometer, it generates a cascade of electrical signals based on resistance which can be analysed to construct an image based on heat signals. When you’re selecting a thermal camera, you want coverage of that long 8um to 13um spectral band – that’s the spot you’ll get best penetration of smoke, fog and rain.

In terms of image quality, options include 160 x 120, 320 x 240 and 640 x 480 pixels. Thermal cameras will usually have fixed lenses, but some are being released with PT and zoom functionalities. Basic control features include freeze/live, horizontal and vertical flip, black-hot/white-hot/etc, colour palette control, histogram display, automatic contrast enhancement, gamma correct ion and digital zoom. Integration with the latest VMS solutions is typically very good.

#sen.news