After great trouble we’ve established increases in impedance in one of our device cables was down to water damage – apparently the drought caused cracking, and this allowed water to get into conduits during recent storms.

We could not understand the symptoms at first – the conduit was relatively new, the cabling was high quality and the plan showed no mid-run connections but when we pulled the cable out of the conduit we found an unshrunk butt connector in the middle – this had allowed water to access the electrical path. If you were looking for water damage during troubleshooting, what signals would you focus on?

A: As water reaches the cable through open connectors or penetrates the cable sheath what you’re going to get first is noise on the wire indicating high frequency leakage between the conductors. This is because water conducts electricity very well.

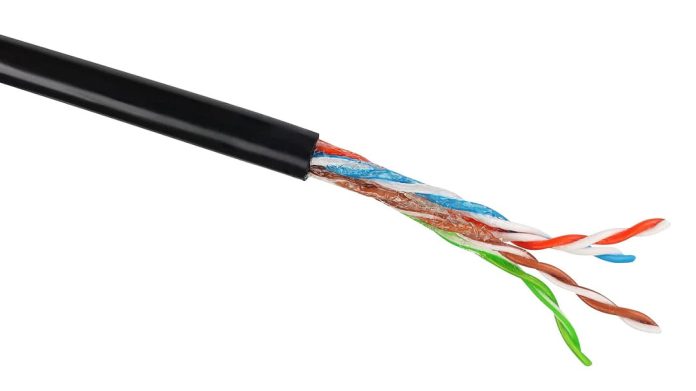

You’ll also get greater impedance, though this may not be measurable, even on an oscilloscope, and the level of isolation will fall. As the copper corrodes further, you’ll get increasing resistance and more noise. Eventually you’ll get constant or intermittent false alarms. If you can’t ensure the conduit won’t leak and the zone is vital, try gel-filled cable.

#sen.news #gelcable