FSH has received SCEC approval (Security Level 4) for its FSS1 high security door monitoring sensor, which has been designed and manufactured in Australia for military, correctional and high security applications.

FSS1 is a big deal for FSH and for the entire high security end of the access control and intrusion detection market, which has been waiting for a solution of this calibre since the Jackson Report found flaws in the security performance of existing high security door monitoring devices. The FSH sensor is available in flush or surface mount variations and replaces traditional high security magnetic balanced reed switches using a Hall Effect sensor and programmable magnetic plate combination that allows the unit to be re-calibrated to circumvent door drop, which would otherwise lead to replacement of sensors or re-hanging of doors.

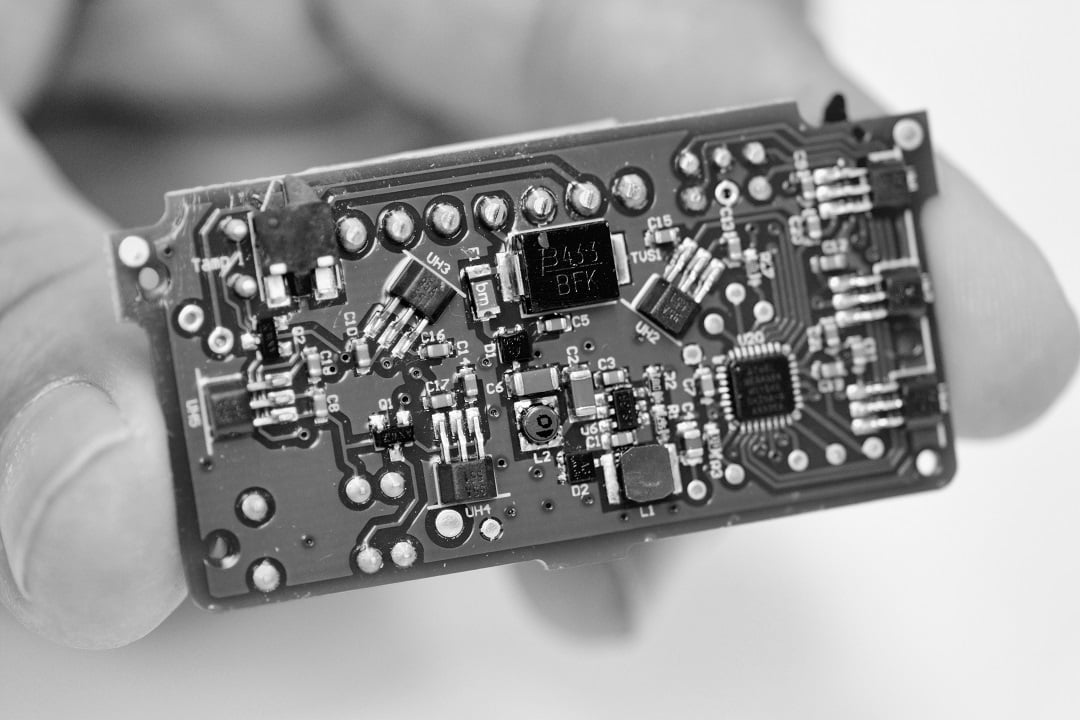

FSH’s FSS1 was developed and is manufactured and programmed in Australia to the highest security standards. This is important for many high security applications. The sensor supports the integration of encryption modules and the FSS1-S and S-NC versions include PCB slots for conduit entry reversal, a cast dimple for drilling cable entry, calibration mode selector and ½-inch pipe thread compatible for existing installations. There are cover removal tamper switches and a magnet array plate. The FSSI-F version has a calibration/mode selector, cover removal for tamper switches, surface removal tamper switch and a magnet array plate.

“The FSS1 High Security Door Monitoring Sensor is the first commercially available active device of its kind with patents granted worldwide,” says FSH’s Marc Bindner. “FSS1 is a quantum leap in door position monitoring, dispensing with the traditional reed switch technology and replacing it with a microprocessor and Hall Effect sensors combination.”

The new sensor was developed over a period of 3 years by the FSH engineering team specifically for high security applications in government, correctional and military installations. It’s a clever piece of design that came about through FSH engineer Mark Aylesbury’s familiarity with the Hall Effect – the propagation of electrical waves outside their conductors – and exploits the electromagnetic properties of magnets to shape the waveform. To that end the FSS1 incorporates 7 magnetic Hall Effect sensors that detect a unique magnetic footprint from an array of 8 magnets on a magnetic face plate.

One of the sensors is used to detect the position of the magnetic face plate in relation to the device, while the other 6 sensors are used to determine the polarity size, strength and position of the magnets on the unique magnetic face plate in relation to the programmed pattern. Taken as a whole, this technology and other characteristics give FSS1 highly sophisticated anti-tamper facilities that are virtually impossible to breach.

“FSS1 is a quantum leap in door position monitoring, dispensing with the traditional reed switch technology and replacing it with a microprocessor and Hall Effect sensor combination”

There are 3 versions – the FSS1-S surface mount conduit version, the FSS1-S-NC surface mount no conduit version and the FSS1-F flush mount morticed version. The sensor has a flexible 10-30V DC input requirement and current consumption is a meagre 75mA. Alarm and tamper contacts are NC and NO. Security tamper proof level is SL4, which is the highest SCEC rating. A particularly strong feature of the FSS1 is its ability to manage door gaps from 1-7mm without the need to replace or re-fit door hardware. This means the sensor can simply be recalibrated to handle changes to door gaps.

EOL capability includes space for 1 or 2 modules, there’s IP67 rating against dust and moisture ingress and SCEC approval to SL4. The FSS1-S conduit version and no conduit versions have dimension of 75mm long, 34mm high and 35mm deep; while the FSS1-F version is 110mm long, 32mm deep and 35mm wide. The surface mount versions have 2 tamper switches to detect unauthorised removal of the cover, while the flush mount version has a separate tamper switch that detects removal of the device from the door frame in which it’s mounted. The sensors are beautifully fabricated and are comparatively discrete, particularly the flush mount version, which can’t be seen when a door is closed.

“What’s most important is that FSS1 is a virtually tamperproof solution,” says Bindner. “It uses a smart combination of Hall Effect sensors and a unique magnetic array plate allowing the unit to be re-calibrated in case of door drop. The FSH sensor is available in flush or surface mount and is developed, manufactured and programmed in Australia to the highest security standards, leading to its SCEC-approval to SL4.”

By John Adams

Fact File:

Features of the FSH FSS1 HSDMS

* Surface and flush mount versions

* High security Hall Effect technology

* IP67 rated against water and dust

* SCEC approved to SL4

* Low current draw of 75mA

* Recalibrates for door gaps 1-7mm

* Designed and built in Australia.