How To Avoid Alarm Zone Noise Induction In Hardwired Applications.

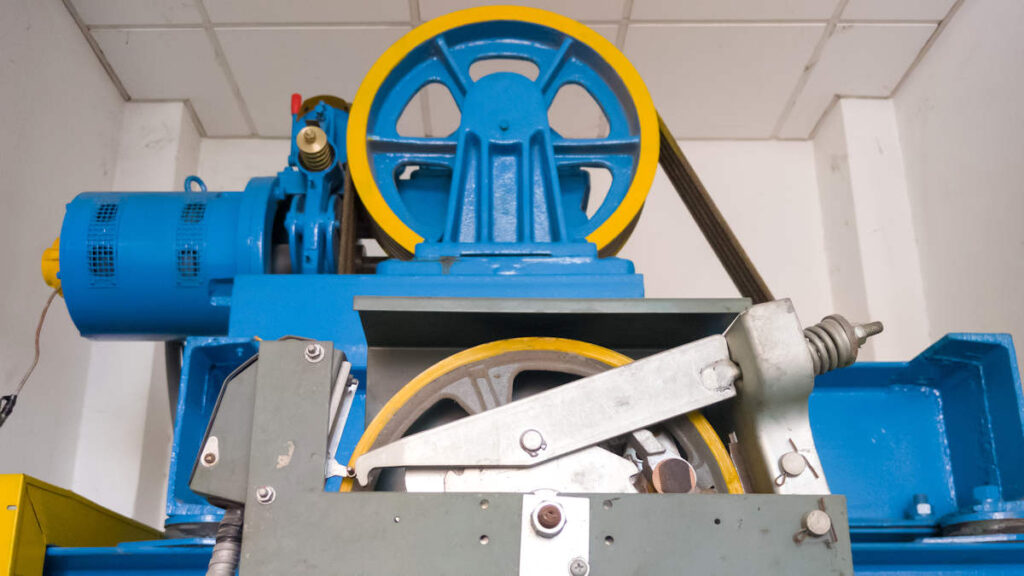

How To Avoid Alarm Zone Noise Induction – Key to avoiding noise induction in wired alarm installations is staying away from sources of EMI and RFI. That’s going to include electric motors, plant rooms, wireless transmitters, power cables and more.

There are also things techs can do within an installation that increase a system’s resistance to induced noise. Keep grounding wires short and straight as possible when installing alarm panels and make sure there are no twists or kinks in the grounding wire.

Never run zone loops and AC power through the same panel knockouts and try to keep them separate inside the panel case as much as possible. Use shielded AC cable, taking the drain wire to the panel’s ground terminal and leaving it unconnected at the plug pack. If zone loops and AC cables must cross paths, make sure they do so at right angles and fix them so they don’t slide alongside each other later.

When you have no choice but to run AC and zone loop cable in the same tray, conduit or through the same header or stud breach, use more zone loop cable than you need to cover the distance. Let the wire coil up a bit and it will be more resistant to induced AC.

Make sure you get your digital multimeter out and check panel ground when commissioning the system. If it differs to other grounds in the building by more than 2 ohms then you’ve not found true ground and you’ll need to try again.

Read the manufacturer’s instructions carefully and talk to experts before trying anything out of the ordinary with equipment you’re installing. Every panel will have a separate grounding terminal – you should be very sure of what you’re doing before you start connecting ground wires to unrelated terminals.

You can learn about Standards Australia’s wiring rules here or read more SEN news here.

“How To Avoid Alarm Zone Noise Induction In Hardwired Applications.”