Is Soldering Best In Tough Environments Or Would You Recommend Alternative Methods?

Is soldering best in tough environments – Would you recommend soldering over all other forms of connection and termination in tough cabling environments or are there better options?

A: We’d argue it depends what you mean by a tough environment. Quality soldering can make a clean and corrosion-free connection that if shrink-wrapped or located in a protected environment will last a very long time and give high levels of reliability.

A particular advantage of solder for connections is that it creates no microfractures in wires being joined. But if soldered joints are subject to fatigue in the presence of constant cable movement in mobile applications or locations where unprotected cables are blown about by strong winds, etc, you’d be better with a quality crimped connection.

It’s also possible for soldered connections to suffer from a range of problems. If resistance builds up in a soldered connection the wiring and the solder will heat up and this may cause the solder to melt, allowing the ends of the conductors to fall out of the connector.

Another issue can be that solder wicks up the cable strands during the soldering process, creating a fragile solid conductor that may break when exposed to vibration or tugging. Soldering is also more time consuming than using crimped connectors with terminal blocks or heat shrink butt connectors for mid-run joins.

Is Soldering Best In Tough Environments

The most reliable alternatives to connecting runs using any of these methods would involve use of pre-tinned stranded conductors, as well as pre-applied heat shrink tubing and pulling it through tough environments inside conduit in unbroken runs, though this might not be possible if you need to amplify a signal. Another consideration is the use of IP-rated connector boxes in rugged locations wherever connections are required.

If you go with pressure connections, a few tips for connector and termination longevity include ensuring terminal diameters are the same size as the fixing screw/nut, including extra conductor wire at the terminal to allow for movement, insulating terminal shanks and ensuring terminal studs, nuts and washers are corrosion resistant and galvanically compatible.

Using spade terminations in terminal blocks is good practise, while slathering on lanolin spray never goes astray – and remember to write checks of challenging cable runs into the maintenance schedule.

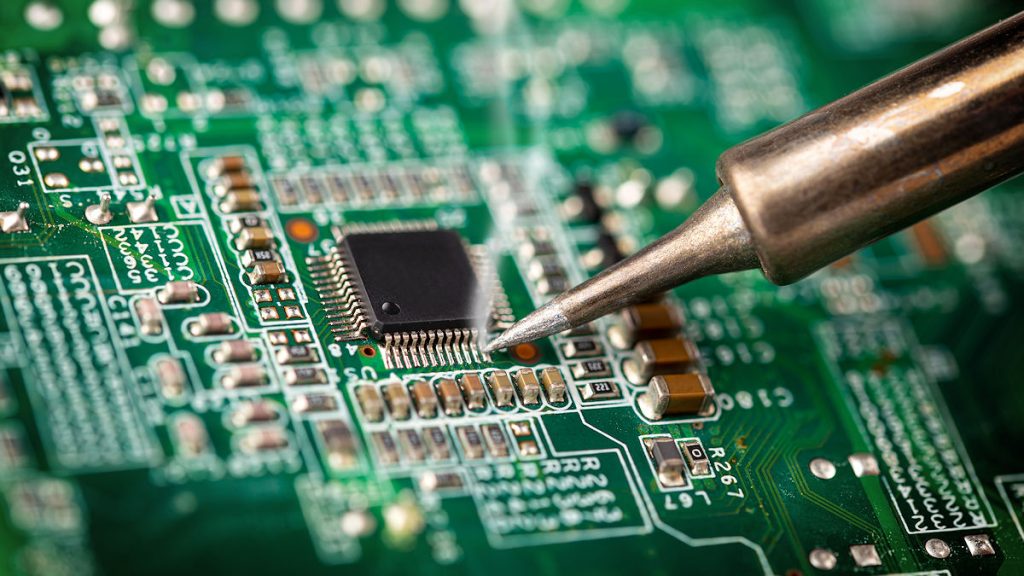

There are connections and terminations that are best undertaken with solder – these include tight spots where it’s impossible to get a crimper head or to faff about with a connector. Re-connecting broken terminations to boards and other devices is also the domain of quality soldering.

There’s a tutorial on soldering here or read more SEN news here.

“Is Soldering Best In Tough Environments Or Would You Recommend Alternative Methods?”