Schneider Electric has installed an Inner Range Infiniti access control and automation solution at the Sunshine Coast University Hospital (SCUH) at Birtinya in Queensland. The integrated security and automation system includes thousands of doors, thousands of devices, 8000 cardholders, and integrates 16 sub-systems, including 360 Jacques intercoms and nearly 800 Pelco cameras.

SUNSHINE Coast University Hospital (SCUH) at Birtinya in Queensland is one of the most significant electronic security integration projects of the past 10 years. At SCUH, a chorus of 16 sub-systems is conducted by a single workstation, giving the security team profound operational sensitivity. But as gripping as this integration is, it’s only a single tributary of an application that pours out at you. A late start, a tight budget, a young team unfamiliar with each other and the products they would be installing, a huge site, an IP network that arrived too late and an access control manufacturer determined to carve out a niche in enterprise solutions.

Operationally, hospitals are complex beasts. A multiplicity of vital subsystems, even core systems, orbit an immutable gravity; the delivering, nurturing and saving of human life. It’s an imperative that feeds into design at SCUH, where meticulous modelling and input from medical staff was used to plan an open architectural design that offered a pleasing environment and fast movement of patients through the hospital. This operational truth permeated the greenfield installation, leeching into build priorities and pressing the Schneider Electric team’s planning through schedule alterations and design variations.

Complexity is everywhere. In terms of floor space, SCUH is the equivalent of five 25-storey towers and even the development of the site has layers. SCUH is not only a hospital but an educational facility and is Queensland’s first public hospital to be constructed under a Public Private Partnership – developed by Exemplar Health, a consortium comprising Lendlease, Siemens, and Capella Capital, with partners Spotless Facilities Services. This collective has undertaken to build and run SCUH for 25 years.

Russell Blake (left), Mike Wood, David Brennan, Mark Armstrong and Ash Ramanayake in the new control room at SCUH

Flying into Maroochydore to meet the installation team, I had a strong sense of the scope of the system but those preconceptions didn’t prepare me for the actuality of a site in the last stages of commissioning before an official opening in March. It’s big – I expected that. But the system itself is very tough to get your head around. In fact, everything about this job was epic – the lead time, the site geography, the network topology, the lateral nature of the huge integrated system with its clever bespoke coding. At SCUH, nothing is simple and everything is entwined.

Russell Blake from Inner Range meets me at the airport and as we head to Birtinya, we chat about SCUH. It’s a conversation we’ve been having for years and it’s nice to be finally getting to grips with a site I’ve heard so much about.

“When it comes to the timeline from our perspective, Schneider Electric won the security and building automation contracts with Lendlease back in 2014 and after a lengthy evaluation process, we were selected to supply an enterprise management solution using our Infiniti hardware and software,” Blake explains.

Russell Blake, Inner Range

“Schneider has installed our products in the past, but this is the first time we’ve worked with them on a major construction project. And this really is a major project. While the University of Western Sydney system is the largest Inner Range site, with 3500 doors and 500 buildings in five locations, in terms of complexity, SCUH takes the cake.”

Arriving at the SCUH precinct and settling into a café across the road, I meet the Schneider Electric team behind design and implementation of the integrated security and automation solution. Project manager David Brennan was first to arrive late 2014. A few months later he was joined by security program engineer Mark Armstrong and site manager Mike Wood – over time the team expanded to nine and managed 50 contractors.

Brennan, Wood and Armstrong have a strong dynamic, presenting the same over-arching operational focus but quite different strengths. All three completely own the application and as we talk I get a powerful sense of the journey they’ve been on. This interview feels like a mission de-briefing after a tough campaign. Later I realise it’s a finely balanced crew. Logical planning and level-headedness from Brennan, strong drive through the intense focus of Wood, and behind these two, all the operational promises and endless complexities of aggregating thousands of devices quietly and meticulously crafted by Armstrong and the software engineers.

“That early time was challenging,” Brennan explains. “At that phase of a project, construction is happening but all of the services are going through some heavy design reviews with input from consultants – every few weeks we would get a new set of drawings for a whole level. With these kinds of jobs, it’s a moving target, making planning more difficult and more vital.

“I’d come from a project with a similar complexity and there was a huge amount of change – I came into this job expecting heaps of changes and when we started we implemented a bunch of stuff to track what we were doing. It’s a lot of paperwork, but as the changes take place it pays off. Careful planning gave us confidence that we were not missing cabling, missing a door, or that there was a drawing out there that was incomplete.”

As well as operational planning a system design was required.

“The first thing we needed to do was quantify the scope of the job,” says Wood. “We had words on paper, but that was about it. Something to consider is that Schneider Electric had won the job very late. We came in cold with very little planning and our team was tasked with making the system happen on a small budget,” Wood explains. “We didn’t have much time to undertake all the backbone designs, the schedules and take-offs but we got them done and that was vital.”

Sitting behind the planning and installation was Inner Range and distributor, CSD. For Inner Range, this application is a watershed – the first major enterprise application of its Infiniti solution. To ensure success, Inner Range maintained an open-door policy all the way through to R&D for the SE team. Meanwhile, CSD provided all the hardware – not only controllers but locks, cabling, the works. According to Brennan and Wood, this intense partnering was a vital contributor to the success of the project.

CSD’s Ash Ramanayake

According to Ash Ramanayake, who handles enterprise systems at CSD, the initial stages of the contract from a CSD perspective came mid-2014 and involved putting expressions of interest to SE.

“We offered not only the Inner Range portion of the installation, but all the locking infrastructure, the hardware peripherals – everything was put together in one package. It took a lot of work to meet the requirements,” Ramanayake explains. “When it came to onsite support we facilitated with Inner Range more than anything else. All the training was handled at our offices – all the equipment and hardware is there. Being a wholesaler, we have warehousing and so the process of working out what is needed is easier for us – we can make sure we have the necessary stock and fine-tune the order with our suppliers as we go along. The whole process from initial pricing to delivery was close-knit – CSD had a lot of involvement with SE around that.”

From the point of view of Schneider Electric, supply was a key factor in the smooth running of the installation process.

“One of the time savers for me was being able to bundle all the access control together from the one supplier. There was only one order from anyone else – it made a difference to the process of managing the order and the equipment flow of the order,” says Brennan. “CSD allowed us to fine-tune the quantities so I would order everything we needed for the ground floor and when it came time to order for the first floor, I would factor in what was left over from the ground floor and order less – I constantly reviewed quantities as we were going and tweaked the overall order.”

According Wood, as the job progressed, Inner Range and CSD put extreme effort into meeting the order.

“We decided about a quarter of the way through to install Inner Range RS-485 SIFER readers and dumped an order for thousands of SIFER readers on Russell’s lap,” Wood says. “It wasn’t until I went down to Inner Range in Melbourne that I realised what the team there was doing to supply us with more than 2000 card readers. On the front line of a job you don’t always see the big picture – you are just pushing and pushing but behind the front line there are people trying to get equipment ready. A lot of overtime went into keeping us supplied.”

The SCUH System

The SCUH site is large, with multiple buildings spread across the campus. Vital to the security system is the network – it’s full Cisco, including switches, design, configuration, engineering and commissioning. The backbone is fibre supported by two main core switches, one in the Facilities Management Centre (FMC) building and one in the Hub building to ensure full redundancy. The verticals sit on top of this fibre and devices are cabled horizontally on each floor in copper. The nature of the network had its own influence on the way the system was built, as did the speed of its delivery.

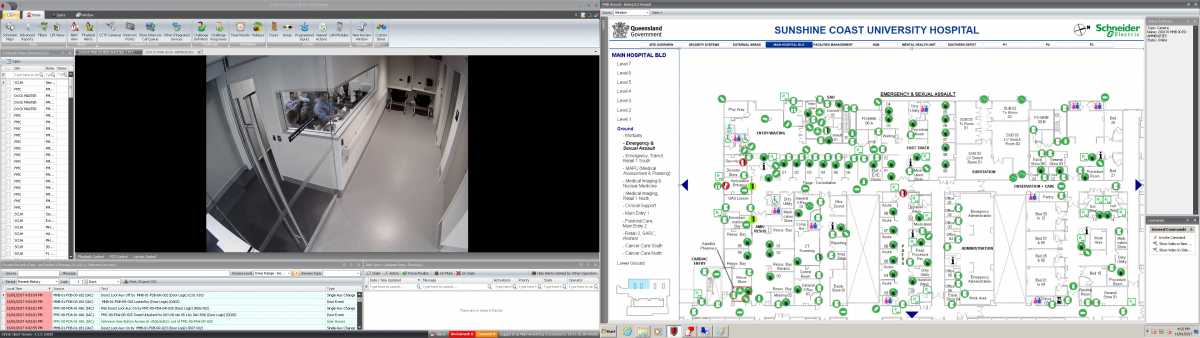

Something that’s tough about SCUH is quantifying the security and automation system. It incorporates so many vital subsystems integrated using low and high level interfaces, that you can’t really define it as a security system at all. At heart, it’s an Inner Range Infiniti security management system supporting a distributed network of 140 controllers and daughterboards handling more than 2000 access-controlled doors, thousands of alarm points, as well as seamless, single workstation integration of those 16 sub-systems. Inside the hospital, door access is handled by SIFER readers, while 15 Prisma terminals arm and disarm security areas.

Subsystems integrated into the security management system include a Pelco CCTV system comprising 800 cameras and Endura storage, Jacques intercoms, the BMS (BACnet/IP), Nursecall, Stanley RTLS (mother-baby matching, asset tracking, patient wandering, mobile duress), KeyWatcher KeySafe, 44 HLIs for the Otis lifts, the fire system (BACnet/IP), SNMP management, web interface, pneumatic tube delivery system, the automated guided vehicle system and more. It goes without saying that there are some areas of Infiniti that were specifically designed or enhanced for this project.

Russell Blake puts it best when he describes Infiniti as an automation hub.

“Infiniti receives and sends information that’s relevant to the integration or service you are providing – it’s a data gathering point for all these different subsystems,” he explains. “The whole purpose of all these individual integrations to Infiniti is to create one operator interface.

“It means operators don’t have to go to Pelco software, then go to Infiniti software, then go to Jacques software and Stanley software. Everything is done through Infiniti – the graphical maps, the alarms, the integrated camera views, the ability to control locks, and mother-baby matching – everything.”

In the network room, the integrated security system sits in two racks, with most of the real estate taken up by the CCTV solution’s 720TB of storage, which gives 30-day real time recording of 800 720p HD cameras. A pair of Dell servers supports the security management system, including Infiniti, Jacques and KeyWatcher. The mirrored servers form a fully redundant virtual environment, built around Microsoft Viridian and incorporating an SQL database. Operationally, three virtual machines sit on each server fully replicated in real time, with dual power rails on different supplies and UPS and generator backup.

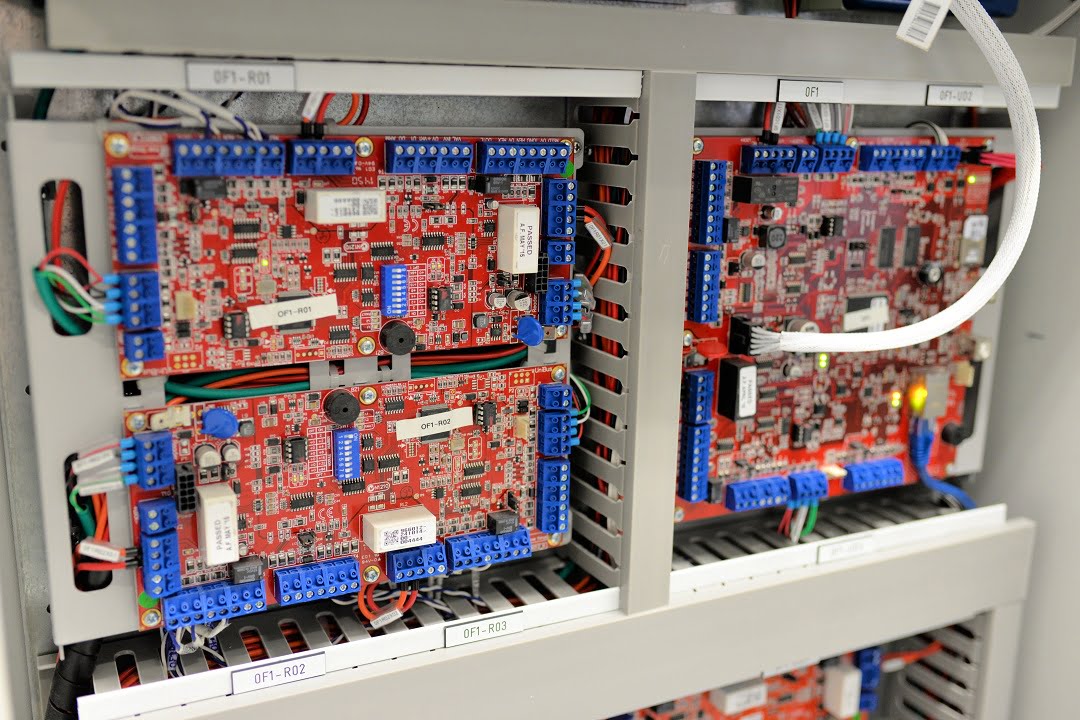

Floor distribution rooms in which controllers and expanders were located formed a vital part of the system.

“Right from the start we had to address what was urgent when it came to getting cables and conduits into walls, but we were also trying to work out the product we were using, how it worked and how it would fit into floor distribution rooms that we knew were short on space – it was a real juggling act,” Wood explains. “We knew we could not use the standard Inner Range panel layout for a couple of reasons – one being space, two being that the consultant had included some IP ratings around the housings, which meant we needed to use Rittal IP65-rated enclosures.

Controller and expanders in customised enclosure in a floor distribution room

“Using these 600 x 600 x 300mm enclosures also meant we needed to go to a full custom panel housing design. To achieve this, we went down a path of standardisation with that customisation because it gave us a standard template and we could customise by putting in or taking out controllers – no box was slated for a particular spot – we could go and build 50, take the top one off and put it wherever we needed it to be. This was important because we did not have a build sequence we could rely on.”

According to Wood, the backplanes were fully customisable.

“We weren’t allowed to use any self-drilling screws on the backplane, they all had to be drilled and tapped – that’s a big process,” he explains. “Drilling and tapping onsite would be a phenomenal amount of work given the number of parts involved so we had this work done at a machine shop. We designed the backplane so it has 150 hole configurations and can incorporate Infiniti Controllers and expanders – that gave plenty of flexibility.

“At SCUH there’s always a main controller in a box and if we need more capacity we install a slave box which includes SLAM (two-door) controllers. Each main controller can be supported by a slave. The way the system is designed, you can just keep adding on. We have flavours of single boxes. There might be one box with a controller and a couple of door controllers hanging off, all the way up to eight boxes in a room.”

Inner Range SIFER reader

“We used the Inner Range double stack hinged flaps – we had to use these and if we had not done we would not have had room to build the system – in some of these areas we have taken all the wall space that was allocated and some boxes are installed so close to the ground that to fit off techs had to lay down on the concrete. The rooms themselves have plenty of height, but the trays are very low so the installation height is restricted to 2200m. We had to take this into account when selecting box sizes – it needed to be big enough to fit all the hardware, while being small enough to fit into the rooms.”

Installing the system

Getting a handle on the installation involves getting a sense of the scope of the site. It includes the Hub/Sunshine Coast Health Institute, including a lecture theatre; the main hospital broken into two parts, the back half with six levels, and the front having three levels divided into hospital and education. Each level has 11 floor distribution rooms but the top floor, which has 10. There are multiple carparks out the back with a childcare centre. There’s facility maintenance. There’s a mental health wing and a mortuary as well. All these parts are linked into the security and automation system, as well as multiple subsystems.

“It was a difficult job in terms of size and layout,” says Brennan. “There was no easy way of carving up the main hospital into coherent parts that could be dealt with one at a time and nothing was replicable the way it would be in a design like a prison. At SCUH, all parts of the site are interwoven and lead into each other.”

Pelco PTZ covering part of the ground floor at SCUH

Because of this, Brennan says the team divided the site on the basis of floor distribution rooms where controllers are located.

“Everything that could be brought back to that room we considered a section,” he explains. “These distribution rooms form a natural aggregation point for the security and automation system, with each distribution room supporting all the doors and devices in a 90m radius around it. The builder had fit-out zones which had arbitrary zones between departments and pushed to finish those fitout zones, whether they suited us technically or not. A system this size needs to be broken into manageable chunks so you can progress through to completion in design, install and commissioning.

“The architecture design made each part of the site unique so it had to be designed from scratch. With sites like prisons, there are design repetitions and there are efficiencies with that repetition but there’s virtually no repetition on this job, nothing compared to a multi-storey. Ground floor was the most challenging, being the most inconsistent floor in terms of design.”

The scale of the cabling was staggering.

“We ended up pulling in 400,000 metres of cable just for the card readers alone and that was using RS-485 daisy chains,” explains Wood. “If we’d used Wiegand star config on this site you would not want to think what the cable quantities might be.”

Architectural challenges in the Hub building…

According to Wood, the team worked hard during the design process to simplify the installation down so it was as easy as possible. This included building ‘flavours’ of controllers that could then be located where they were needed. Different flavours incorporated selections of SLAM expanders and backplane configs, depending on what was required.

“The theory was that we would do almost all the installation of controllers and expenders at SE, including fitting the hardware into the floor distribution rooms so sub-contractors only had one point of termination,” he explains. “The subbie then simply terminates the wiring and takes inputs up to the controller.

“We used Inner Range smart power supplies as much as possible to give us more control and easier and quicker installation and commissioning. Where we have had to step up the output on power for mag locks we have had to use some third-party power supplies. All the panels are installed with battery backup internally, and mains power is supported by UPS and generators.”

Michael Wood, Schneider Electric

According to Wood, every powered device, including locks and PIRs, sits on a fuse connected to a fire relay allowing the security and automation system to fail open in the event of fire.

“This site is designated as a gathering point for the public in the event of a disaster so it’s seismically and environmentally rated,” he explains. “This meant that across the site, as well as in the floor distribution rooms, there are installation rules we needed to conform to.”

When it came to the physical installation, Wood says the toughest part of the job was the Hub building because it had the most architectural flair.

“It was a difficult to run cable and in some places, we had to mount readers on glass panels.”

Challenges of the application

You expect big applications like this one to have challenges and SCUH is no different.

“At the start of the project the biggest challenge was that everything was new – we were pulling together a new team, dealing with working for a new company, learning about products we’d never used while planning for an application that was at once enormous and nebulous,” Brennan says. “We really were scrambling and fortunately Inner Range gave us great support through that. They must have been sick of all the questions but we were given access to the developers and got excellent support. I don’t think we could have dealt with that period as well as we did without that level of engineering support.”

As the build progressed, the biggest difficulty for the team was ensuring they got network support where and when they needed it.

“Our security system runs on multiple VLANs on a huge converged network,” Wood explains. “It was our biggest problem and risk having the ICT contractor managing the converged security and automation network. The backend of the project was a constant battle with the network – primarily delays in waiting for network points to be made available. In part, it’s understandable when you consider the co-ordination of getting a very expensive network installed into a messy and complicated construction site so we can start installing and commissioning an electronic security system – it’s very tricky.”

According to Wood, an issue from a planning perspective is that the builders on the ground did not understand the impact the network had on everything else.

“October 2015 was meant to be the network finish date, but the builder’s understanding of what constituted a complete network was that the data centre was built – no switches, cabling or configuration – just bricks and mortar,” Wood says.

“The completed network was meant to finish at the same time services provider including us were supposed to be finished, so technically the ICT cabling guys would be pulling the last camera points on the same day we were supposed to have the last cameras commissioned and operational,” Wood says.

“The difficulties extended to the working out whose network points were whose was an issue here – it was a jumble of points without a schedule and we all just had to work out which was whose. Not easy.

“The network was peppered with flaws as well – it was by far the worst part of the job from multiple different aspects and that hurt us badly.”

Brennan agrees.

“The network was our biggest challenge – at times we couldn’t simply commission or test,” he explains. “There was a lot of time spent on coordination and any fault we found that was not ours took a long time to rectify. Many stakeholders, including Cisco and its engineers, were not in Australia so everything was difficult. You might spend an hour finding a fault was not your cable but in an adjacent network component, but you’re not allowed to touch it even if you can see what’s wrong and you know how to fix it and the alternative is waiting a week for someone to come along and fix it. This was a major challenge.

“It’s a tricky situation because on major sites like this everything is IT, everything is networked, there are more and more devices. The network needs to be the central aspect of everyone’s planning for big jobs – the network, the rooms that support the network, the cable path, the fibre runs,” he says.

According to Wood, there were operational complexities, too, and these fed into development of the management system, in particular, the database and its permissions.

“Spotless is managing the site as a sub-contractor, but Spotless doesn’t know what each person’s role and permissions are around the site – the hospital just tells Spotless what these are,” he says. “The client wants to have permissions tied to job titles, but they need to consider the risks involved – that database will need to be 100 per cent maintained.

“We are contracted to the builder, but Spotless is our customer operationally speaking so they were very interested in the best possible operational outcomes over the long term and then they would support what we wanted to do. But it’s tough – everyone involved has different goals – especially as the job winds down. The builders want commercial acceptance and we are having more interfacing with end users and trying to keep both happy.”

Another issue for the team was cable supply.

“At the time, we started working on this job there was an undersupply of cable around the country,” Wood says. “At one point, there was six weeks during which we could not source new cable and we chewed through our stock, getting down to the last 10,000m before re-supply. When you consider we were pulling 5000m of cable every week we came very close to grinding to a halt.”

Security Control Room

Next, we set off for the security control room and as we go I get a chance to take in the site. It’s huge. There are strong architectural characteristics impacting on the application – cameras must deal with intrusive design and there’s the slat-based design features create lines of sunshine and lines of shade that challenge my DSLR. There’s a lot of internal light, large areas of glass, vaulted ceilings.

At the security control room, I ask SCUH Spotless security manager Marc Phillips how things have been going.

“The site is obviously not open yet but the security and automation system is working well,” he says. “Our security team of 30 staff better understands the intricacies of the system. One of the biggest learning curves is knowing what access rights and levels can be given to people in certain roles. The more access they have they more they can do and we may not necessarily want them all to be able to do it – that’s been one of the biggest things for us when it comes to security management of the site.

“Even though the site is not fully operational as a hospital, the system is busy logging staff and contractor movements. The system allows us to stay on top of doors being propped open which dilutes the effectiveness of the access profiles – as we move into an operational environment we may get fewer alerts, as the system will be used as intended and the activations will not be false alarms generated by workers moving around the site. In that context, education of site users is a big thing – they need to understand what the consequences of their actions are and the events their actions may instigate.

“Moving forward, we will integrate the Stanley RTLS solution next,” Phillips says. “Given the nature of the system, mobile duress is just another software package that comes up on our management workstations. Certainly, our preference is to run everything from this software – we don’t want multiple pieces of software. Aggregating events also means we only see the events we need to see.”

SCUH security manager, Marc Philips

According to Phillips, in the lead up to the official opening of the hospital, the security team has undertaken comprehensive testing of the security system.

“We’ve tested every duress alarm on at least four occasions and there are more than 600 physical duress alarms – it’s been no mean feat and was complicated by the fact many areas of the hospital have been clinically cleaned so you can’t access them without scrubs and clearance from the area director,” Phillips explains. “Consistency of testing has also been a big thing for us. You might test in one way the first time and get a result, but test in another way the next time and have issues.

“This testing is vital because the Spotless security team report to Queensland Health on the readiness and effectiveness of the system and the only way we can be certain of what we are appraising them of is by testing. Once the hospital is fully open there’s a test schedule we must adhere to for mobile and fixed duress points and that will be even harder once the hospital is fully operational.”

SCUH operator in the control room

When it comes to system management, Phillips says everything is pretty much up and running and configured and ready to go.

“What we like most is the centralised management on our authorised workstations,” he says. “As well as being able to see alarm events across the site with associated video footage, we have integrated photo ID cards. In the future it’s possible that our cards will become multi-technology and incorporate access control, photo ID, drug cabinet access, library access, as well as being a payment card for vending machines.”

The control room, which is a narrow-ish L-space incorporating the video wall, which supports 780 cameras, 180 of which are located on the ground floor. The video wall is comprehensive – there’s SIP integration of intercoms – when they are activated a light comes on, the relevant camera view is called up on screen as the PTZ goes to a pre-set at the intercom, all done through Infiniti, Jacques and the CCTV system. There are two SMS workstations with Infiniti software, the Pelco software and the Keywatcher software on them, one of which is the main terminal the security team works from. There’s also a dedicated CCTV workstation that can be used by police if they are on site and need to undertake investigations locally.

Integrated KeyWatcher cabinet

The control room also houses a Keywatcher cabinet – it’s one of three located around the site – two solely controlled by Spotless directly and one controlled by Queensland Health. There are three types of intercoms here – the audio slave, the video slave and the video master.

“The Pelco system has been solid – we’ve only had issues with 1 camera throughout the entire application, which is good performance,” says Wood. “This control room is the place we did all the programming and configuration for the system – it wasn’t as tidy as this back then, believe me.”

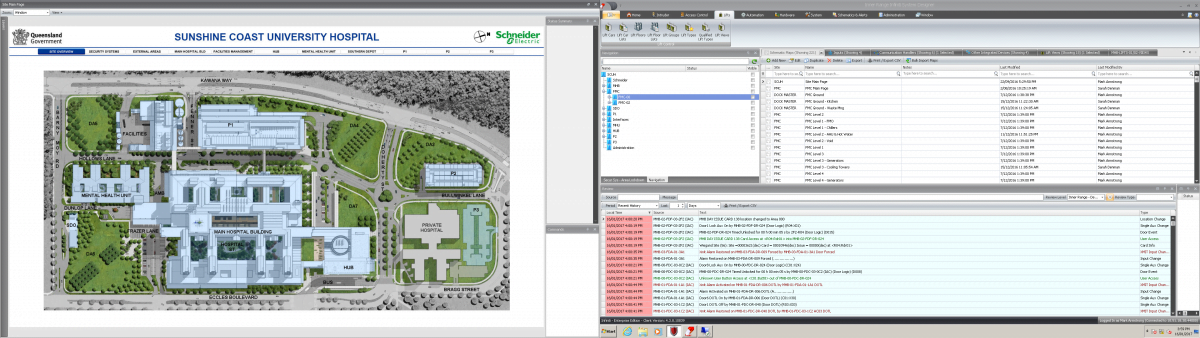

Overview of the Management System

It goes without saying that the Infiniti management system is a heart of this solution and our next port of call is a security operations desk adjacent to the Emergency Department, where the team gives me a run through of the integrated system. According to Brennan, Infiniti has considerable programing flexibility that the team used wherever possible to simplify the installation, its commissioning, as well as future maintenance.

“Mark and Jeremy didn’t just build a database – the schedules they built took into account multiple different things right down to the current draw out of each panel so that as they entered the door types and the hardware associated with doors, the system would alert them to the fact power to that door was being over-used and the panel would need to be upgraded,” he explains. “It was not just about how many slots there might be on the panel, but the number of devices associated with a door. We automated all that using formulas so when you entered fields around a door, it would give you that information immediately based on previous calculations.”

This programmability infuses everything about Infiniti. Mark Armstrong is driving the Infiniti software using a map-based GUI and I can see how densely populated it is. According to Wood, SE focused on the maps as the primary user interface and worked hard to make sure the maps the engineers built for Infiniti were customised so they looked similar to the BMS.

“We wanted the system to be map-based and to look like the BMS to make it as easy as possible for operators using both systems to navigate the site,” he explains “The results speak for themselves. For instance, I don’t know where Medical Imaging is in the hospital but if I click here, the system will take me there via the maps or I can get there by search. There are hundreds of maps and they pop up instantly in the event of an alarm.

“The buildings are clickable from the main site page – you click through to buildings and then drill down into the system either graphically, or via the tree directory,” Wood says. “Each floor plate bubbles up alarms. For instance, if there’s a duress alarm you click on the building that’s red, the floor that’s red, the section that’s red, the room that’s red in order to find its location. And we can undertake lockdowns of individual locks, of departments, of floor, of the entire hospital.

“With Infiniti maps, there’s no latency – with other products there might be a 20-second delay – maps are not opened in multiple windows, they open one map at a time so you don’t get lost. The flexibility is fantastic and operators can contrive their own ways of viewing and managing the system.”

Woven into the GUI is access control, alarms, CCTV, intercoms, BMS, Nursecall, Stanley RTLS (mother-baby matching, asset tracking, patient wandering, mobile duress), KeyWatcher KeySafe, Otis lifts, the fire system, pneumatic tubes (just releasing of the canister) and automated guided vehicles.

Fully automated RTLS vehicle heading out of a lift

“Stanley’s RTLS handles mobile duress, asset tracking and baby-mother matching that automatically manages access control,” says Wood. “Each baby has a worn tag and the maternity ward has 13 low level interface doors. When an unauthorised baby approaches an exit point, the Stanley system sends our system a signal and Infiniti locks down that door then unlocks when the baby moves out of the field of the door reader. And if someone tampers with a baby tag, the whole ward goes into lockdown until someone acknowledges the alarm on the Stanley system.”

Emergency help point

The duress alarm allows Armstrong to demonstrate some customised features that Blake calls ‘bespoke enhancements’ of C sharp code that applies logic to creates in-software tools able to save integrators hours or days of work. In this case, when a duress alarm is activated and called up in the management software, the system brings up a customised box that includes things like a CCTV clip of the event with pre-event and post-event recording and a notebook.

Mark Armstrong, Schneider Electric

“One of the beauties of Inner Range is that you don’t have to build everything individually – we can create a duress point type and then apply it to multiple locations instead of having to create hundreds of duress points,” explains Armstrong. “Same with changes to these points – you don’t change points multiple times but only once – that’s wonderful and it allowed us to simplify the programming. For instance, we have a number of different door types and instead of going to a door and programming it to a type, we go to a type and select the type we want doors to be.

“We created a lot of backend tasks to make things work – we don’t want people to come along and adjust our backend tasks. We can achieve this by pulling areas across to the backend so it can’t be accessed. Something else that’s great about the Infiniti system is how customisable it is. You can change things all over the screen – move boxes, change colours, you can add more information. You have full CCTV control allowing you to pan around; you have so much flexibility through one box.”

According to Wood, from an operational point of view, this is so much more powerful and flexible than a traditional video wall.

“In an event, a camera view might be thrown up on a wall but what does it mean, what is the operator trying see? How do they manage the event?” asks Wood. “The way the SCUH system has been put together is interactive and tailored. Investigations are also easy. You click on finalised alerts, find the date and time and then click and you have the event, you can see the operator that actioned an event.”

Jacques Intercoms are installed throughout the SCUH site

“With typical access control systems, you install it and walk away from it – it can unlock doors and you can change how doors are unlocked and who can unlock them, but you are not watching the system 24 hours a day. This system is meant to have someone sitting at a workstation and having full view of the entire site and full control of the site – multiple events across the site simultaneously, on two screens with one instance of software.”

According to Wood, Inner Range’s custom engineering was a big help for the SE engineers.

“For instance, we needed to programme 60 SIPs (Security Information Points), so Inner Range built a bespoke enhancement that essentially says ‘if you see this, do this’ and we just have to put a couple of fields into the bespoke enhancement and all those 60 integrations are done instantly,” he says. “Creating code is beyond us and Inner Range saved our bacon – it allowed us to get on with what we do well.”

Conclusion

Sunshine Coast University Hospital is a beautiful, purpose-built facility that was designed with considerable input from medical staff to be one of the most efficient hospitals in Australia. The security and automation solution is cutting edge, contriving to merge multiple sub-systems into a single workstation while retaining layers of redundancy, as well as full off-network distributed intelligence. The process of installation was intensely challenging and was pulled off by a young team thanks to excellent planning, considerable drive and a stack of technical nous.

“Schneider Electric SE has done it right at SCUH,” says Blake. “When it comes to the physical layer, they have enterprise-grade dual redundant servers and all the best hardware. The team took the bull by the horns from an engineering perspective. They fundamentally understood how the system was built and they configured it in such a way that they got the best bang for their buck. They built all 221 of the maps in Infiniti from scratch. This site is incredibly complicated, but the Schneider Electric team distilled it down so it’s very simple and very manageable for operators.”

Meanwhile Wood has plenty of praise for Infiniti.

“Integriti is fantastic – we could not have done the job with a lesser quality product and nor could we have done the job without the support we got from Inner Range and CSD – that support really opened our eyes,” he says. “The speed this thing was moving, if we had had roadblocks in support we would have been overrun but we consistently got the most complex issues sorted out very fast. We started behind the eight-ball in terms of time and money and pulled it together thanks to this product and the people that support it.” ♦