One of the gems in the Aritech range is the DD400 Series dual technology sensor which combines all the best things the company’s R&D team have come up with over many years.

FIRST up there are 3 sensors in the DD400 dual technology range. They include the DD450 – which is 12m with 7 curtains (reducing to 7 or 5m), the DD470 – which is 16m coverage with 9 curtains (reducing to 10 or 7m) and the DD490 – which offers 20m coverage with 7 curtains (reducing to 12 or 7m).

Basically, the folks at Aritech took all their best PIR technology and all their best microwave technology and shoe-horned it into a single housing. On the PIR side the DD400 Series has sealed Gliding Focus Mirrors with proven 4D signal processing. On the microwave side Aritech is using a microwave module with Twin Opposed Antennae. The advantage of this configuration is superior signal to noise ratio, as well as enhanced directional detection from the microwave, which is important given microwave’s bulky signal shoulders.

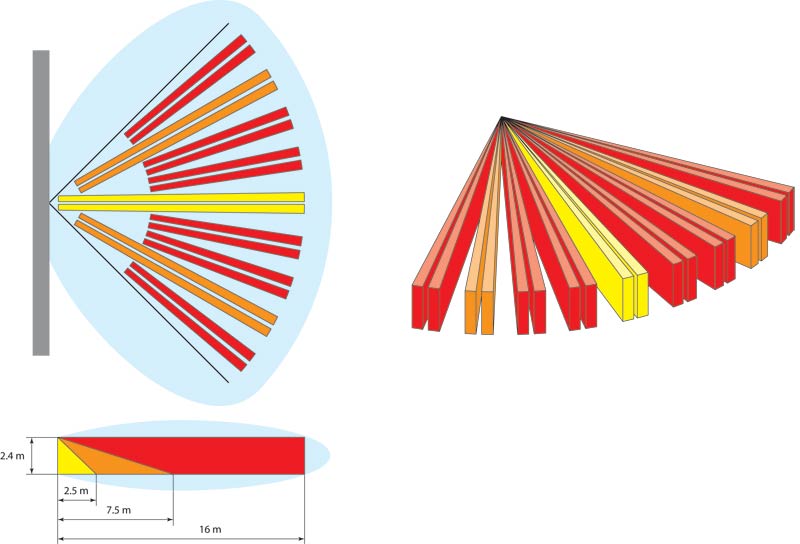

DD400 Lens Pattern

Sensors is the DD400 range have solid curtains of detection. Full undercrawl protection gives maximum security while the special characteristics of a curtain ensures not only better intruder detection but also better PIR stability from the environment. A further advantage is better performance in warm environments where conventional PIR’s optics experience loss of range.

Aritech’s patented Step and Gliding mirror optics is at the core of its PIR technology. Essentially, the mirrored lens surface is designed to create a continuous curtain of detection coverage regardless of the focal point location in the sensor’s range. The gliding mirror design gives complete coverage of an entire scene.

Standard PIR lenses can create lanes of sensitivity that might be just a few inches wide but many metres apart at the extremities of a sensor’s detection range. In comparison, Aritech’s mirror optics covers every single part of the scene in view with such accuracy that it’s possible to use supplied masks to cover particular areas.

The design of Aritech’s mirrored lenses also allows the reflected IR in the target area to be compensated for on the basis of range. That means the voltage generated at the pyro by an intruder is identical whether the person is standing 2 metres from the sensor or 12 metres from it. And this sense of perspective allows speed of movement to be compensated for with perfect accuracy, too. From an installer’s point of view, there’s no calibration with an Aritech gliding mirror sensor. The signal received at the pyro is consistent regardless of the distance the intruder is from the sensor.

Another key property of Aritech’s gliding mirror technology is that it gives a sensor the ability to autofocus’ on an IR source in the target area perfectly and with no need for adjustment of sensitivity. Typically with other PIR’s, in smaller room the pulse count will be turned down to reduce sensitivity and avoid false alarms. Trouble is, this makes the sensor much easier to defeat by crawling or creeping, especially on warm days.

Aritech DD400

So what’s with the 4D PIR signal processing? Aritech breaks its analytics up into a process levels. 1D processes based on shape, 2D on duration, 3D on speed, 4D on size and 5D on environment. With 4D processing, the DD400 range processes based on shape, duration, speed and size of signals. Moving Pole Filters recently added to the 4D processing ensure real immunity to tough environments.

When it comes to microwave the DD400 Series uses Distance of Motion (DoM) Processing. This proprietary microwave processing converts the analogue signal into a digital one so the sensor’s ASIC processor can measure the distance travelled by the intruder, irrespective of speed or distance from the detector. This gives a significantly more uniform microwave signal over the entire protected area and prevents microwave detection hot spots close to the detector.

Something else that’s neat with the DD400 Series is that it’s able to adjust PIR and microwave channels simultaneously using that Gliding Focus Curtain Mirror we met earlier. That means it’s possible to reduce how hard the detector is working in smaller rooms, in both the PIR and Microwave channels, making detection even more stable, without compromising catch rate.

The DD400 units with anti-masking deploy active infrared and light guides in the detection of masking. The light guides allow the AIR to protect fully both the PIR and microwave technologies. According to Aritech, the most sophisticated masking attempts made to disable the detector, using a wide range of materials, are automatically reported to the control panel.

The DD 400AM operation and reporting are easily field-programmable making it flexible enough to meet the requirements of any application. The DD 400AM also performs its own regular self-test of the PIR and anti-masking functions, reporting any discrepancy automatically to the control panel.

In terms of general specifications the DD400 Series target speed range is 0.2-3.0 metres per second while current draw is 14.5mA. The unit has normally closed contacts, a 1.8-3m mounting height, an alarm time of 2.5 seconds and a temperature range between -10 to 50C at 95 per cent humidity. The sensor’s field of view is 86 degrees.

DD400 Series housings meet IP30 which decree the survivability of a 5kg object from 40 cm height or a 200g object from 10 cm height, as well as IK02-10, which means the sensor is protected from tools and wires greater than 2.5 millimeters but not from liquids. Sensor dimensions are 126mm x 74mm x 54mm.

Fact file:

* 3 models offering 12-20m ranges

* Wall and ceiling-mount bracket supplied

* High performance PIR verified by HQ microwave module

* Precision sealed ‘gliding focus curtain’ mirrors

* Twin opposed microwave antennae

* Custom dual technology ASIC processor

* PIR with 4D signal processing

* Microwave with advanced proprietary DoM signal processing

* Extremely low microwave power with optional day disable

* Alarm memory versions (selectable control polarity)

* Excellent RFI and white light rejection.