Q: We are responding to a tender in which we have been asked to install part of our system in an flameproof enclosure for a mining application – could you give us an idea of the complexities of installing such equipment?

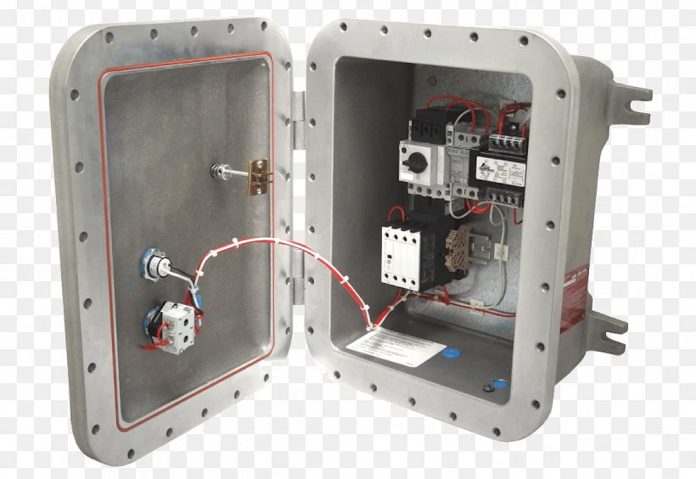

A: Flameproof enclosures are used for push-button switches, isolation switches, solenoids, lights, and control and measuring devices that might generate heat or emit sparks that could lead to explosion of environmental gases.

You’ll need to have one eye closely on the standards for an installation like this, and a maintenance program will need to be agreed upon up front. Locally, flameproof enclosures are covered by the Australian Standard/NZ 2380.2 and this standard should be your best friend when planning any system for an explosive environment. There are comparable standards in the U.S. and Britain.

The design of these enclosures ensures that any explosion, built up of excessive heat through resistance, or any spark generated within the enclosure, will not breach the enclosure, and will prevent any spark, flame or heat venting to the explosive atmosphere outside the enclosure leading to ignition.

Flameproof enclosures allow installation of power and arcing devices within high-risk areas – this means that ordinary equipment can be installed within the enclosures. However, installing an entire flameproof system in a high-risk area is expensive and time consuming. This is serious kit – a single cast aluminium enclosure may weigh more than 10kg.

Something else to note is that flameproof enclosures are not typically waterproof, or weatherproof. And you can’t modify them to make them so without voiding your explosion proof warranty. If you need help locally sourcing custom gear talk with Melbourne-based hazardous area solutions designer and manufacturer, NHP.

#sen.news