The Alarms Corporation has installed a powerful Honeywell Vista 250 Turbo on a V-Plex LAN at the Dick Johnson Racing workshop and racing museum on Queensland’s Gold Coast. Supporting the alarm, access control and automation system is a CCTV solution comprising Honeywell cameras and a DVR.

Contents

Honeywell Vista 250

Honeywell’s Vista 250 Turbo is one of the company’s standout security management solutions, handling intrusion detection, access control and automation, as well as supporting Honeywell’s awesome V-Plex bus. The solution installed for DJR also incorporates Honeywell Tuxedo, giving a sweet local interface for system management and automation, as well as the capability to remotely manage the system.

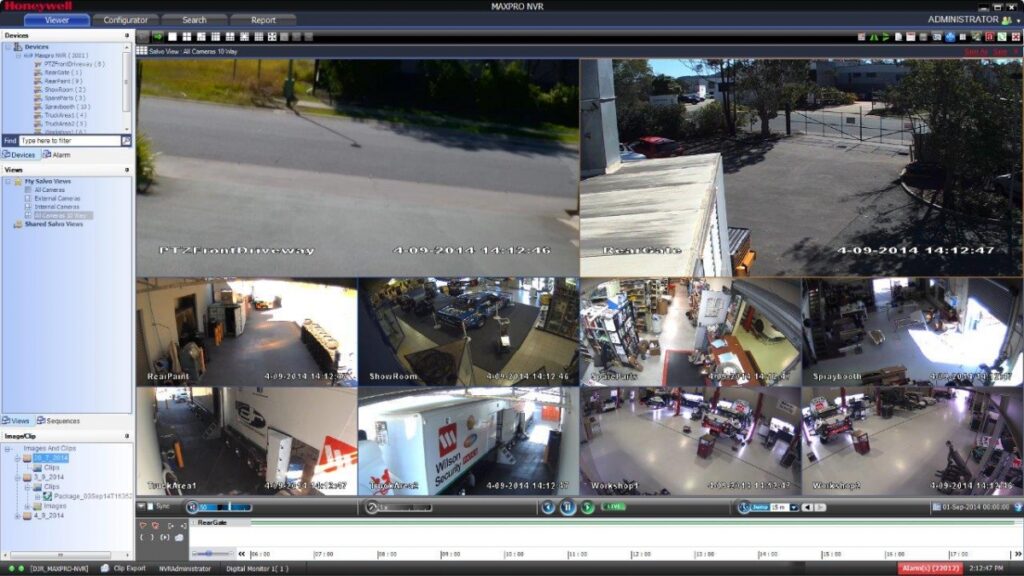

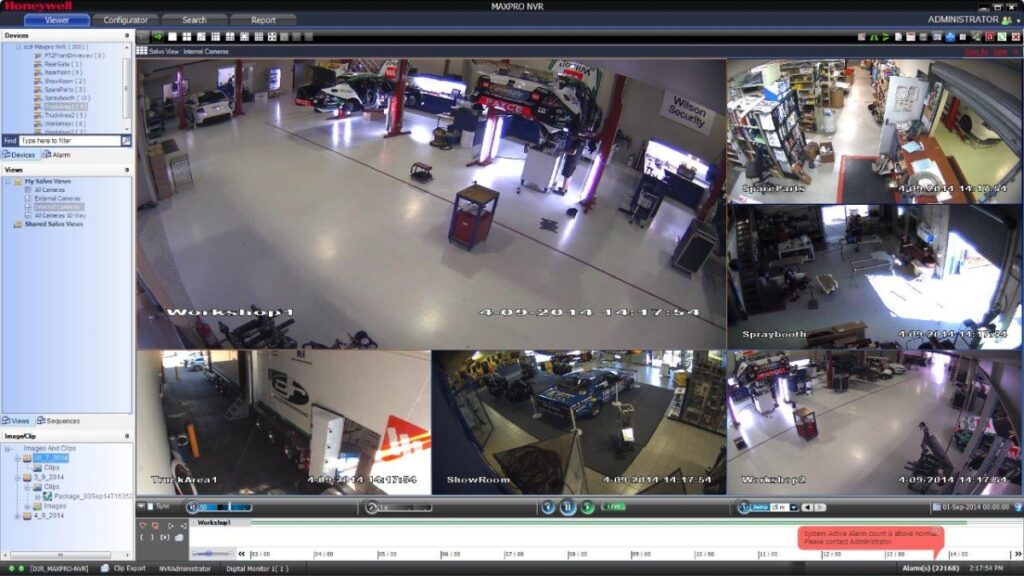

This application includes a 32-input Honeywell Maxpro NVR with 8TB of storage supporting 10 Honeywell HD cameras of various types. Important to bear in mind is the fact CCTV is integrated into the intrusion detection system, giving the solution a video verification capability as well as a measure of intelligence.

I meet Honeywell’s John Gellel and Glenn Webster of The Alarms Corporation at Brisbane Airport, and after a buzz down the motorway to the Gold Coast, we arrive at DJR. As soon as we walk through the front door, our eyes go straight to Dick Johnson’s Windsor 351 V8-powered XD Ford Falcon Tru-Blu sitting in pride of place in the middle of the museum floor. There’s a ten-second hiss on my voice recorder that captures the moments we stood silently and stared.

Dick Johnson Racing Museum

It’s a pleasure visiting the DJR museum at multiple levels. I was at Bathurst’s Mount Panorama Circuit in 1980 when Dick Johnson hit that infamous rock while leading the race. Quintessential Aussie battlers, Johnson and wife Jill had mortgaged their home to buy an ex-Queensland Police XD Ford Falcon pursuit car to run in the Hardie Ferodo 1000 – 163 laps around a gruelling 6.2km course considered the toughest touring car race in the world.

Thanks to the Kingswood in our garage I was a Holden boy and was at the track supporting Peter Brock’s Commodore. But it was hard not to feel for Johnson, and downright impossible not to feel a deep thrill as the public spontaneously raised the money to replace his wrecked car via an impromptu telethon while the race was still taking place. Johnson’s raw response to the generosity of fans occupies a very special place in Australian sporting history.

As well as being a home for his memorabilia, including 8 original race cars, this facility is the home of Dick Johnson Racing, and out the back in the workshop, we can see 4 race cars in the process of being fitted out or repaired. There’s also a jaw-dropping Queensland Police Ford Falcon pursuit car being tweaked in the workshop. The vehicles, components, tools and intellectual property of DJR have considerable value. And it’s a big site, too, much bigger than I was expecting. The total floor space is around 2000 square metres.

The Alarms Corporation, Honeywell and DJR have taken security seriously and the result is a thoughtful solution that makes the best use of Honeywell’s gargantuan product range. As we walk through the museum towards the workshop, Honeywell’s John Gellel points out a case containing the basalt cannonball Dick Johnson hit that far-off day at Mount Panorama. At the bottom of the case is a tiny wireless accelerometer sensor reporting to a wireless receiver at node zero. It’s a level of detail I see a lot of at Dick Johnson Racing.

Dick Johnson comes over and joins us for a tour of the site. He’s a lovely bloke – very direct, matter of fact and quite devoid of ego. Johnson seems very much the same man he was in 1980 when he took a tilt at the world’s most challenging touring car race as a privateer. In the moments between fascinating motor racing stories coloured by his laconic humour and native courtesy, there are sudden flashes of the drive and focus that made him the motor racing legend he still is.

Was there a specific thing you wanted from the security system, I asked him – you obviously wanted to protect the place, but did you have an idea in your mind? I ask.

“I wanted to know remotely who was in here and when – for a number of reasons including safety, time and attendance, but also just be able to keep an eye on things via iPad while we are away at motor races,” Johnson replies. “Internal security is something we have to consider, as well as keeping an eye on punters turning up and wanting to put things from the museum in their pockets.”

Alarms, Access and Automation

DJR was not a greenfield site. When the building was completed in 1998, a C&K Sierra solution had been installed, which meant there was considerable legacy 4-core cabling installed throughout. This is important because it was the Honeywell V-Plex LAN’s ability to reuse legacy cabling that makes this such a unique installation.

When the system was planned, the design team decided to project the alarm system outside the facility to increase the amount of time available for response. The result is classic onion skin layering of detection, with external curtain PIRs (driving PTZ presets) covering approaches to entrances, reeds on external and internal doors and multiple volumetric sensors through the facility, which combines a number of very large open spaces with smaller offices and workshops.

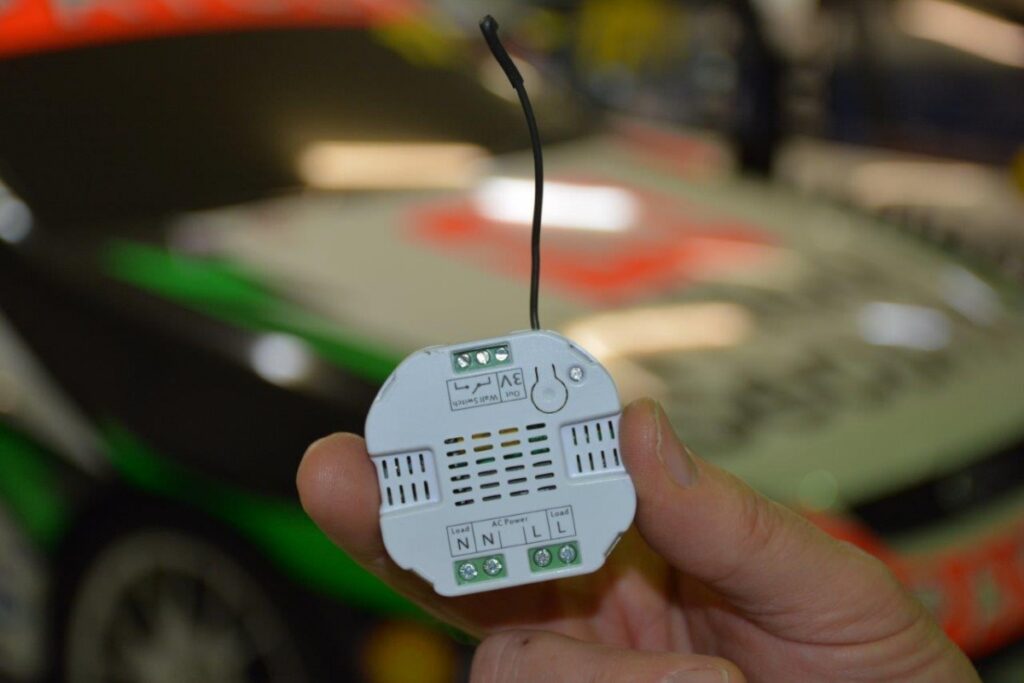

“(Honeywell Vista 250) V-Plex is the heart of the system,” Gellel tells me. “The Alarms Corporation team converted all the original 4-core cabling to a 2-wire V-Plex bus. In this way, they were able to use the existing cables, as well as add additional alarm devices onto the same cables.

“One of the beauties of V-Plex is that you can keep adding devices to the LAN by tapping into it at any point and in this case we have tripled the number of detection devices and we’ve only needed to run a couple of extra cables in a daisy-chain from existing sensor points.

“In terms of the cable layout, we’ve retained some of the star configuration of the original system but V-Plex means we have the ability to branch out from any sensor point and then bring alarm signals back into the star. Whenever there’s a need to expand, the integrators just tap into one of the existing branches using a short cable run.”

Under the hood at Dick Johnson Racing is Honeywell’s big Vista 250 Turbo control panel, which combines intrusion alarms, access control and support for automation. It’s a powerful unit and that turbo nomenclature has real meaning. Vista 250 Turbo hustles a souped-up processor that allows faster processing of multiple events across the V-Plex LAN – whether these be alarm, access or automation events. According to Webster, the panel’s faster processor is noticeable operationally.

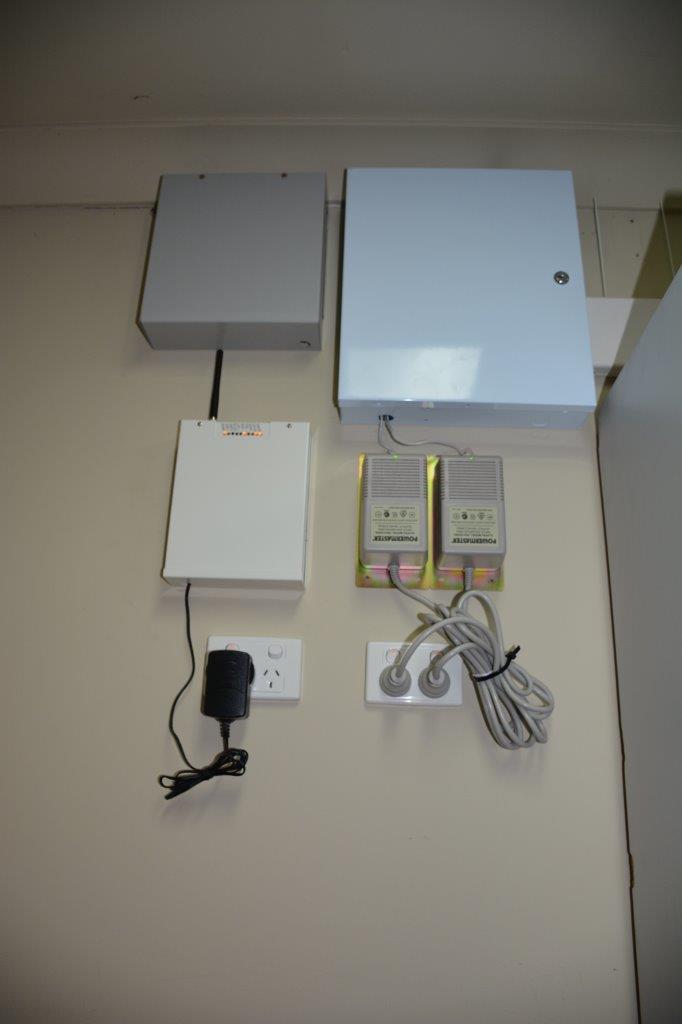

We take a look at node zero, which comprises a couple of panels tucked in a secure area. By default, this had to be where the old panel and all its zone loops had been installed. In this room, there was no sensor, so a V-Plex sensor has been installed here, too. The control cluster includes 3G GPRS (there’s PSTN backup), Honeywell’s Vista 250 Turbo and a wireless receiver alongside the alarm panel (there’s another in a different location to improve range).

At Dick Johnson Racing, all the detection devices with the exception of the 2 external PIRs guarding the entrance, the asset protection sensor on the museum’s rock case and one reed switch on a centrally located aluminium and glass door (345MHz), are hardwired. In all there are 63 alarm sensors in the system and all are new.

There are reed switches on a number of external doors and internal volumetric sensors, which are Honeywell Dual Technology 74s and 75s. Meanwhile, the external sensors are Honeywell 5800 Outdoor (OD) dual technology sensors with a 12m range. These sensors are very reliable, incorporate sun shades and are wireless, which is extremely convenient from an installer’s point of view.

“The system is designed with a pair of PTZ cameras covering the driveway and gate, and these PTZs link with the external sensors via programmed presets,” Webster explains as we take a look at the external components of the system.

“The way it works is that if one of the external sensors goes into alarm, the relevant cameras will swing around and focus on the entry so as to verify intrusion. After a set time and in the absence of further triggers, the PTZs go back to their home position, viewing the driveway.”

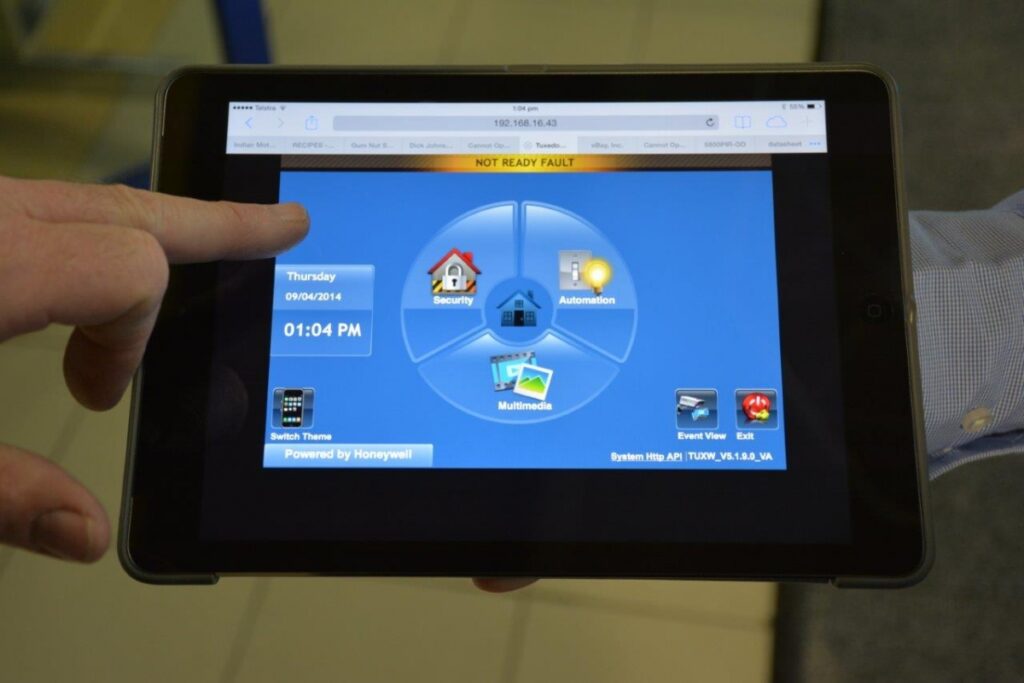

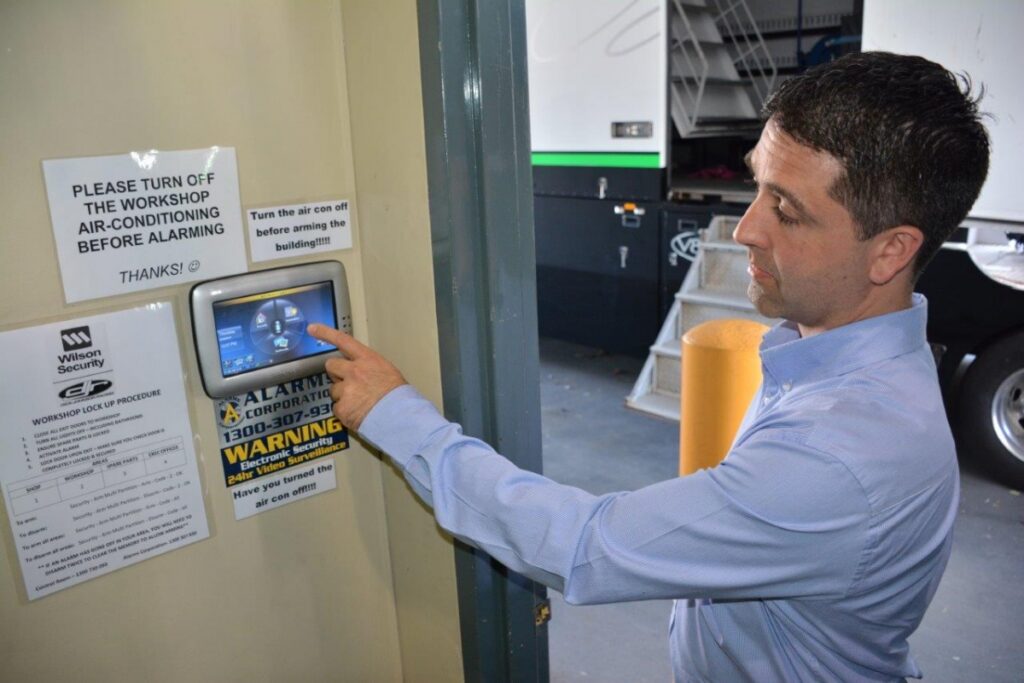

Next, we go and take a look at the Tuxedo user interface. It’s one of 4 user interfaces driving the system at Dick Johnson Racing – in all there are 2 keypads and 2 Tuxedo touchscreen user interfaces. As regular readers know, Tuxedo is a special beast that manages automation integration as well as system management on behalf of Honeywell Vista 250 – 12, 48, 120 and 250 control panels.

“As well as arming and disarming the system, we use Tuxedo to handle automation functions, including managing lighting,” Gellel explains. “For instance, if an alarm is activated, Tuxedo triggers the lights to come on to assist the cameras.”

In essence, what Tuxedo facilitates is the ability to create if/then responses to situations. It’s deceptively simple to set this up, yet it gives the system much power.

“You can set up different types of scene with Tuxedo – for instance, at Dick Johnson Racing, we’ve set up a scene condition to turn on lights in the event of a particular alarm event – an if/then condition,” Gellel explains.

“When you set up a scene, there are 3 parts – the condition, the trigger and the action. The condition could be a certain time of the day or a state of the system – armed or disarmed.

“For instance, I might program the system so that if at a particular time of night – say 6 pm onwards, and the system is armed, then special lights are activated for a specific period of time, allowing late working staff to exit the building safely. The same applies to access control events – they might trigger lights or air conditioning.

“In another condition I might program the system so that when the thermostat is above a certain temp, it will trigger an additional air conditioner to power up. In terms of setting up these automation scenes, the installer can do it during commission or the end user can do it later on.”

It’s a nice interface, the Tuxedo. We’ve reviewed it before in SEN but spending an hour with a product 18 months ago can’t be described as having familiarity with the product. Watching Gellel tap-dance through setting up an automation condition reminds me how intuitive this solution is. Tuxedo’s wizard really makes life easy for installers.

The Dick Johnson Racing CCTV Solution

On the surveillance side at Dick Johnson Racing are Honeywell 1080p and 720p HD cameras installed on a Cat6e subnet. There are a number of fixed external cameras, as well as a couple of Honeywell’s ruggedly handsome HD Series PTZ domes installed under the eaves.

Externally, things are challenging from the perspective of cameras. There’s a lot of strong backlight looking out from covered verandas across the carpark, with plenty of glare from the cement walls of Dick Johnson Racing and adjacent buildings.

Inside are fixed internal domes, which are doing a great job in variable conditions. In most areas, the internal light is quite good in the daytime, with plenty of artificial light in support, but there are open docks and workshops, as well as plate glass windows, meaning lashings of the backlight to contend with.

Next, we take a look at the workshop floor. At this point, I have to confess that Dick Johnson Racing is a challenging site to visit given there are old and new racing cars all over the place. We do our best to focus on the security system and ignore the huge V8 engines and shiny metal components all around us.

The workshop comprises multiple work bays with lifts and lighting, which are covered by the internal domes. They’re relatively discreet, these Honeywell domes; even when they are being pointed out to me, I sometimes don’t see them. Because of the open design and the height of the space – about 2.5 stories floor to ceiling in my estimation – a small number of cameras is able to command excellent views of the workshop. Lighting is handled by metal halide pendants – around 400 watts each – which gives the cameras plenty to work with. Colour cameras love metal halide.

We set off to view the workstation handling video. Again we find it hard to walk around DJR (Dick Johnson Racing) in the company of Dick Johnson without getting side-tracked by racing cars. Look, there’s a reed switch, and there’s a shiny racing car with an enormous 645hp V8 engine! And there’s a fixed internal IP dome, and there’s a racing car with its transmission and gearbox hanging out! Do they really put the gearbox at the back in these new cars, Dick? In short, it’s a heck of a lot of fun.

Eventually, we get to the workstation in its own office. It’s a tidy setup. There are 10 cameras on a dedicated subnet, so it’s not a vast head end. The cameras are running at 720p and 1080p, around 12fps, depending on the job they are doing. The Maxpro NVR unit installed here has a capacity of 32 inputs so there’s bags of room for expansion when required. Gellel drives the system fluently – it’s an intuitive cockpit, the Honeywell Maxpro VMS.

“It’s a good image outside – there’s a lot of backlight out there,” I observe. “And look how the internal domes in the museum are seeing out through the plate glass into the glare and across the carpark.”

I’m not alone in my admiration for the system.

“And the images are so clear,” Johnson agrees. “This system is the whole ten yards. You can pretty well see everything throughout the place, which is great.”

This latest generation of IP cameras really is the business with backlight. A few years ago, IP cameras could not do things like this. The angle of view is good, too. A single Equip Series 1080p camera installed high up covers pretty much the entire store and museum and gives good colour rendition.

Looking at the VMS I can see Honeywell’s (Honeywell Vista 250) internal cameras do an excellent job in a number of challenging locations on this big site. Some of the camera views over the workshop floor are about 30m deep, and the same cameras are getting useful views into adjacent workshops that are easily 50-60m from the lens. It’s these long views from the fixed cameras that show the WDR performance. There’s strong sidelight from huge open doors streaming in at around 50m from the lens, and we are still doing better than just situational awareness.

The Installation

According to Webster, the physical installation of the system was a relatively quick process once all the planning had been undertaken and all products sourced.

“We had 4 guys on the job for 4 days and then there was another couple of days of commissioning,” he explains. “We were working 10-12 hour days, so that made the process shorter. The DJR crew arrived between 6-7 am so we could make an early start.”

According to Webster, one of the key aspects of the alarm system upgrade was the changes that have taken place across the site since the original system was installed 16 years ago.

“Since 1998 new walls have gone in, and things have moved across the facility, and these changes meant there were gaps in the system,” explains Webster. “What we have done with the new Honeywell solution (Honeywell Vista 250), along with replacing all the existing sensors, is fill in the gaps created by the evolution of the site.”

As the boys walk me through the alarm system, Webster points out the location of an original sensor point in the workshop that has been re-designated as a 2-wire V-Plex LAN.

“That’s an old 4-core cable over there in that vertical conduit,” Webster says. “From an installation perspective, we just took the old sensor off and then put a 2-wire V-Plex sensor on. Over there, we did a similar thing with a V-Plex reed, daisy-chaining from the sensor.

“That’s the beauty of V-Plex. If you want another device in the system, there’s no pulling in and terminating a whole cable run; you just tap off the nearest device. We did that here, we did it down there at the next sensor, and we did it all down the end with that reed.

“It makes expanding the system so simple,” Webster says. “All we had to do was tap into an existing sensor point and run 2 wires from there, to there, to there and then address the sensors so the panel would know which was which.”

Now we look at the camera installation. Whoever installed the cameras did a nice job, I observed. It’s tidy work – no loose stray loops of cabling, and everything is straight and true. When it comes to challenges, Webster says there weren’t any really hard things about the installation; it was more of a process to work through, though there are always little aspects of any job that stand out.

“From our perspective, the things that took up our time included the additional cable we had to run if we could not V-Plex existing alarm zones, which really shows how convenient V-Plex made the job,” Webster says.

“On the cabling side, the cameras were the hardest part,” he says. “One of the particular challenges we had to find a way around relates to the gutter running all the way around the edge of the veranda roof line. This roof design meant there was no frame at the edge of the building on which to mount cameras covering the driveway, gate and front door.

“What we needed to do was bring these cameras under the veranda, which took some care, because we needed to cover doors and the driveway with the same cameras.”

Given the available fixing points, the only answer was a custom mounting bracket.

“And the good thing was that if the installers needed something like a bracket to hang cameras outside under the veranda, we could just make one in the metal shop instantly,” Johnson chips in.

“That was a big help,” says Webster. “Sometimes when you install a camera on the supplied bracket just because of the nature of the mounting point and the mounting hardware and the angle of view you are looking for, no matter how much you rotate the camera, the view isn’t right.

“We could go to the DJR metal shop boys and ask – can you make a bracket that does this and this – they’d just knock it up, we’d install the camera, and we could turn to wherever we wanted. This gave us a lot of flexibility.”

As well as the PTZs at the front, Webster says at the back of the site where the DJR semi-trailer is parked, the IR light wasn’t being directed in quite the way the installers needed.

“Again, the DJR boys made a bracket that could direct the IR light perfectly for us,” says Webster. “The guys here at DJR were fantastic – nothing was a problem, which always makes for a good working environment.”

Conclusion

This is a great solution, and it was an enjoyable case study from my perspective. Not only is it an excellent job from the integrator and Honeywell (Honeywell Vista 250), but this system reflects well on Dick Johnson Racing, too. Management has taken security seriously and the result is a system with classic onion skin layering combined with the power and flexibility of automation. It’s a system that will offer a high level of protection for many years to come.

Many of the electronic security systems we look at are fundamentally modular – they don’t have the level of integration this one has, particularly given the comparatively modest size of the application. DJR brings together access control, intrusion detection, CCTV, lighting, air conditioning, and anything else the future might hold.