Contents

Sydney Harbour Tunnel Digital Upgrade

Sydney Harbour Tunnel Digital Upgrade – Sydney Harbour Tunnel has upgraded its existing CCTV system with additional integrations, enhancements to the management system and video wall, and a distributed controller architecture. The installation of new IP cameras delivers improved performance, as well as onboard analytics that SHT will use to count vehicles, as well as to deliver an additional layer of fire protection.

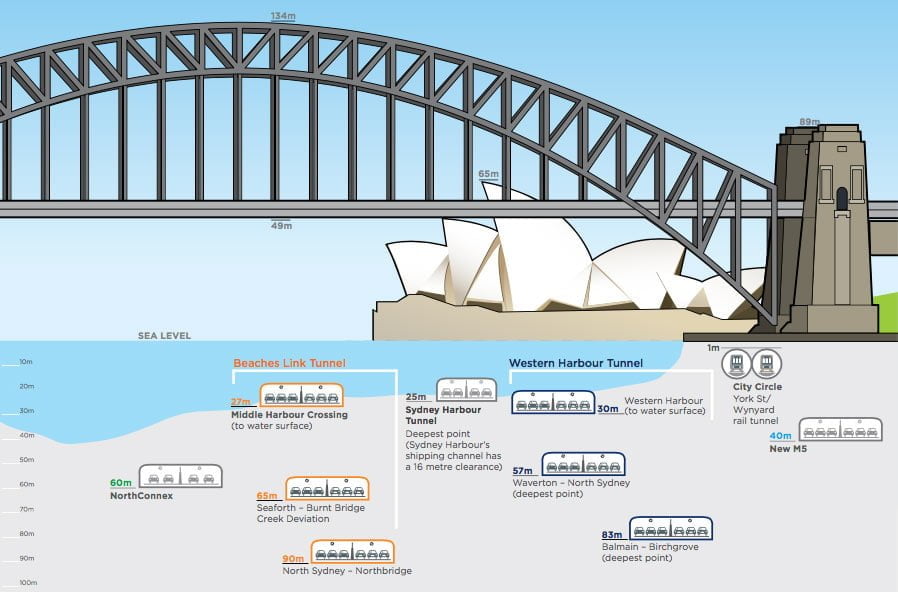

SYDNEY Harbour Tunnel is a vast piece of infrastructure that’s central to traffic flows across the city of Sydney. It comprises a pair of 900m land tunnels on the north side of the harbour, a pair of 400m land tunnels on the south side of the harbour and a 960m immersed tube containing 4 lanes of roadway.

Last upgraded in 2013, the analogue solution at Sydney Harbour Tunnel incorporated a mix of Panasonic, Sanyo and Bosch fixed and PTZ cameras linked to a Trantek MST developed management solution, called VMT, via encoders and a fibre ring backbone. While the old system was robust and extremely reliable, it was time to upgrade cameras and the management system, and the decision was made to undertake a system-wide digital upgrade at the same time. Now that the current digital upgrade is completed, the new SHT system is fully digital, fully automated and fully integrated.

An upgrade of this nature is a highly complex process. Enhancements to the head end of the surveillance system and the video wall need to be undertaken at quiet periods for simple changes, or with new and existing systems running in parallel. Any upgrade of the system must be modular, must expose minimal points of failure and can never impact on live monitoring inside the tunnel. Meanwhile, new technologies – like the Bosch IVA being used to detect fire – must go through an extensive period of testing before being integrated into the over-arching management solution.

While there can be no downtime of management systems that support Sydney Harbour Tunnel, physical works inside SHT also require careful planning and can only be conducted at times when the tunnel is closed to traffic. This meant camera replacement progressed at the rate of around 4 cameras per week during the period of upgrade.

Something to note is that the Sydney Harbour Tunnel’s network is supported by an extremely robust 2Gbps fibre backbone, currently in the early stages of upgrading to a 20Gbps upgrade, that forms a single logical ring. This backbone is made up of 2 fibre rings, so if one is lost, the other remains available. The fibre goes around the whole tunnel via existing trenching and emerges at control racks and control points throughout the tunnel. There are multiple core switches supporting cameras and other devices in the field, and an additional set of links is installed between each core switch and the field equipment connects to a second core switch for increased redundancy.

Managing SHT CCTV

Managing SHT is a central control room at North Sydney, supported by a second control room located nearby that can be deployed whenever required. The VMT4 management system was upgraded with a fully integrated SCADA and VMS solution developed in Australia by Trantek MST Pty Ltd. This product, denominated AMT5, natively integrates the Bosch cameras, with the integration achieved with support from Bosch Australia and Claude Rizk from the Controlware team. One of the features of the integration achieved by the AMT5 product allows Sydney Harbour Tunnel to avoid expensive camera license fees, as well as allowing developers to focus on key areas of functionality that are specific to the SHT application.

As well as avoiding expensive camera license fees, there were operational imperatives that made a fully integrated and locally developed and controlled management solution the right choice for SHT. A key aspect for the team is that to deliver the highest levels of situational awareness in real time, everything needs to be synchronized and the challenges of managing this layered process through other commercially available VMS solutions meant it was easier for a local development team to develop the required functionality directly within their system. This approach, as opposed to integrating different vendor products through layered subsystems that often check for license limits, is the only guaranteed way of consistently achieving low latencies with sub-second response times.

With AMT5, SHT operators use a keyboard to switch cameras over the network to PC-powered monitors in a similar way to old analogue switchers. Importantly, from the point of view of operators, procedures are related to camera numbers, and this allows very fast and intuitive management and response in live monitoring applications. Central to the process is that the system is programmed in such a way incidents in a particular camera’s field of view generate a response based on the part of the tunnel in view. This means all Sydney Harbour Tunnel’s emergency traffic plans can be actioned via a single camera number.

The overall system managing Sydney Harbour Tunnel is customised using the AMT5 SCADA configuration scripting language and this system is integrated to the CCTV system so that signage, ventilation and fire response can be actioned in sections based on the where incidents occur in the tunnel.

From the point of view of operators, you type in the camera number, look at information at the bottom of a page displayed, and this shows the area of the tunnel being viewed and what steps must be taken – for instance, the sprinkler system (known as a deluge system), exhaust fans and emergency messaging in the event of fire. It sounds complicated written out like this but in the control room you can see what’s happened and how to respond in a glance.

Sydney Harbour Tunnel Digital Upgrade

I visit SHT during its recent upgrade with Brad Ballesty and Leigh Davies from Bosch, Claude Rizk from Controlware and Leo Ascone from Trantek MST to get a sense of where the team is up to in the process, as well as to see the installation of the latest cameras in the SHT tunnel. We start out with a visit to the main control room, which is also in the process of upgrade to add further integrations, as well as adding new automation to existing functionality.

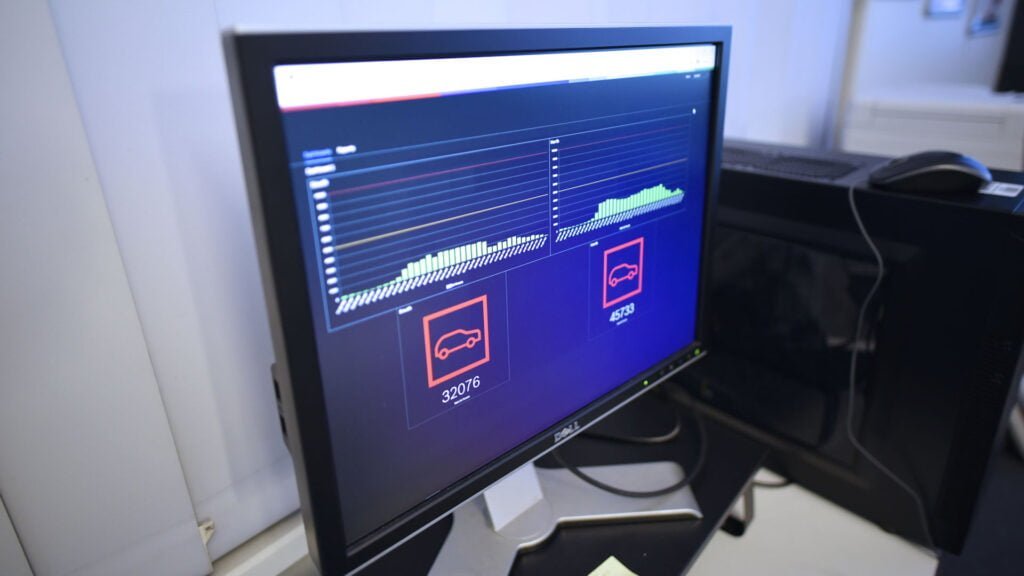

In Sydney Harbour Tunnel’s partially upgraded main control room, the top 3 video screens of the video wall display the tunnel graphically, show north and sound bound traffic flows, air quality, air flow and CO levels in the tunnels, the current traffic plan, message boards, exhaust fan operation, pump operation and more. Under these monitors are CCTV monitors displaying a cross section of cameras selected by operators based on prevailing conditions.

Using the AMT5 constellation of servers, operators select cameras live or recorded, drive PTZs, address traffic plans, manage ventilation fans and check and set message boards. This management capability is replicated at the remote site allowing SHT staff to monitor and manage SHT and its systems from a second location, independently from the main site, should this be required.

Along with the move to end-to-end IP, the upgrade has included replacement of the video wall, the replacement of the old analogue tunnel schematic map with a monitor-based version, and the ongoing integration of all relevant subsystems. There’s also integration of alarms with video – this process was still under development during my visit, but it includes over-height vehicle alerts, and vehicle ID, as well as beta testing the integration of the Bosch AVIOTEC cameras, which provide high quality optical views as well as using IVA to detect fire.

According to Trantek’s Leo Ascone, a key element of the upgrade has been the implementation of distributed central controllers.

“The traditional way to manage systems is through a central database,” he explains. “With this upgrade we have moved to a distributed model, with controllers located in different parts of the system. What controller distribution means is that there’s no single point of failure and this can be achieved with less complexity and expense that it could be in the past, when you needed to duplicate key components to give redundancy.

“The development of technology over the past 10 years makes a distributed model easier to implement. Hardware is very reliable and rarely fails, while software tends to fail very predictably.

Once a software solution that is mirrored in lockstep locks up it doesn’t matter how many of them you’ve got, you’re in trouble – what we are aiming to achieve with the CCTV and SCADA system at SHT is many software actors are working in parallel with their own timing so that when timing bugs occur only one or two servers having the precise timing might fail while others survive thus achieving a naturally survivable system where there is no single point of failure, except for the camera itself.”

Ascone says the way the system has been designed focuses on redundancy and that means the design is role independent.

“Having all the key systems separate means that if you have a single software failure, or a device or component fails, it’s just that point of failure you lose from an operational perspective,” he says. “The completed system, which is built around Trantek MST’s proprietary software platform, works very nicely.”

According to Ascone, the shift away from analogue taking place as part of the upgrade has changed the way CCTV is used at SHT.

“Because we are going to digital there’s a lot of focus on analytics and metadata and the ways in which that sort of information can be used to streamline our operations and give additional information,” Ascone explains. “In the case of these Bosch cameras, the metadata and analytics are in the camera and if you want to use them, they’re already there, which makes the deployment process easier.”

Bosch’s Brad Ballesty points out that Bosch’s latest cameras and systems are designed to be predictive and to give all the information needed to run a successful operation straight out of the camera.

“There are 124 Bosch cameras being installed at Sydney Harbour Tunnel – 40 MIC 7000i PTZ units and 84 AVIOTEC 8000 fixed cameras in wedge housings, which provide fixed angle views, as well as delivering fire detection via IVA,” Ballesty explains.

As well as the AVIOTEC cameras there are also traffic counting cameras – these are the highly capable Bosch fixed Autodome 8000i units, which count traffic going in one direction to accuracy levels above 90 per cent – more accurate counting is made challenging by the fact large vehicles can block camera views of smaller ones. A key aspect of the upgrade is integrating these new Bosch IP cameras and their video streams, metadata and analytics into the existing management system.

“When the solution is completed, the way the AVIOTEC cameras will work is that they will not only trigger the exhaust system, but the sprinkler system as well,” says Ascone. “They’ll achieve this by being hooked into the new distributed controllers, which will also allow events to be reported back to the control rooms.

“In the past we drove this process through the camera numbers but with the Bosch IP cameras and the network upgrades, we’ll be doing it with the camera metadata processed for incident detection and the presence of smoke and flame, information which will be integrated with another fire detection system, allowing for greater accuracy and additional automation.”

Ascone explains that operationally what will happen is alarms from the AVIOTEC cameras will come into the system and there will be a decision as to whether the incident is a fire depending on whether one system detects the event and not the other, or whether both detect the event. Operators will also be alerted and will be able to click on an alarm and view incident video, giving visual verification.

Getting this right has been a team effort, with input from the manufacturer, software developer and operators. According to Ballesty, Bosch’s involvement in the SHT application involved supplying the cameras, as well as taking on additional tasks like coding firmware were required.

That’s unique agrees Rizk, because with a Bosch camera you can request the iframe come up faster than it will with an ordinary camera type, and if you call an iframe independently, when it comes up, it’ll be synchronized with the rest of the system – vital for live monitoring and reviews.

“Something interesting was that there were issues with reflections from the emergency lighting of fire trucks – the lights caused events to be activated – the way that was managed was via written code in order to slightly reduce the sensitivity of the IVA,” Rizk explains.

Touring Sydney Harbour Tunnel Digital Upgrade

After checking out the control room and the IVA workstation under beta test, we inspect the Northbound SHT tunnel, where a team from HSC Security led by Neville Tannous is busy installing the last of 40 Bosch MIC7000i PTZ cameras in support of 84 Bosch AVIOTEC fire detection cameras, as well as a small number of traffic counting cameras. To highlight the challenges of working on a busy road tunnel, we arrive at SHT around midnight and it’s much later when we head underground.

When compared to typical video surveillance applications, the scale of road infrastructure is immense. The journey from the Sydney Harbour Tunnel control room to the closed North-bound tunnel to check out the process of camera installation, as well as the Bosch AVIOTEC cameras, highlights the complexity and huge size of this site. It takes 25 minutes from the time we hop into the car to the time we pull up alongside the HSC Security installation team.

The PTZs being installed at SHT are Bosch MIC 7000i cameras – when SEN tested an earlier version, we found it was an absolute weapon on the street, delivering extraordinary performance in a rugged package first developed for marine applications – qualities that make it ideal for life in a road tunnel 25 metres under the sea.

Bosch’s Leigh Davies asks the technician working on a scissor lift whether he needed to use the instruction manual because it was his first time installing the Bosch MIC. According to the HSC Security tech the process was so straightforward he figured it out by himself within a matter of minutes. According to the HSC tech, physical installation is fairly easy, though the bolts in the base can be tricky in this application when working alone, because the holes are quite small.

We also check out the Bosch AVIOTEC IP starlight 8000 cameras, which are installed in the centre of the tunnel at 60 metre intervals. The 1080p AVIOTEC cameras operate stand-alone and don’t need a separate evaluation unit. Each camera contains all features of the Bosch Intelligent Video Analytics, which allows analysing and evaluating moving objects in parallel. Video-based fire detection and Intelligent Video Analytics operate independently from each other and are separately adjustable. Importantly, these cameras perform well in low light.

Also important is to ensure the ideal angle of view and focal point is achieved to deliver best IVA performance – this process is being undertaken with input from operators in the SHT control room. A key element of the process is that the distance between cameras must be tuned for analytics so as to ensure performance is as accurate as possible. When the system is completed and all functions integrated there will be analytics for fire, as well as a heartbeat from cars travelling through the tunnel to detect normal traffic flow.

According to Neville of HSC, as well as ensuring the cameras are correctly positioned, another aspect of the installation was ensuring the cameras are not too close to sprinklers and not too close to walls which are regularly washed, as the AVIOTEC’s are full body cameras installed in third party housings.

“The HSC Security team has tested everything from the tunnel niche to the camera, all cables are tested, and all the devices have been pinged from the switch and are working as they should,” Neville explains.

“Once everyone is happy with the images, we hand the new IP CCTV system over to Leo and the 2 systems will run side by side for an extended period in case there are any issues.”

After chatting with HSC Security team, we pull over multiple times, checking out old cameras, including some venerable Sanyo models, as well as seeing encoders in control boxes, which until the IP camera upgrade, carried analogue signals onto fibre for their long trip back to the network room. At all times the enormous size and complexity of the site are overwhelming.

Sydney Harbour Tunnel Digital Upgrade Conclusion

Sydney Harbour Tunnel’s IP CCTV upgrade is part of a system-wide digital transition that will significantly enhance operation of one of Sydney’s most important pieces of infrastructure, delivering increased redundancy and reliability, as well as higher levels of automation.

The key take-away from my visit during the Sydney Harbour Tunnel CCTV upgrade were the complexity and delicacy of delivering an upgrade like this one in support of an application that requires near 100 per cent up-time. Another highlight was the serious nature of the partnerships between supplier, integrator, SHT operators and management, and the software development team.

All are intensely committed to ensuring Sydney Harbour Tunnel has the best possible solution, now and into the future.

You can read more about Bosch CCTV solutions here and read more SEN news here.

“Sydney Harbour Tunnel Digital Upgrades CCTV Solution.”

How did they build the Sydney Harbour tunnel underwater?

The Sydney Harbour Tunnel consists of 8 reinforced concrete immersed tube units, each 120 meters long and weighing 23,000 tonnes. Each unit was prefabricated in Port Kembla, towed to Sydney, floated into position, sunk to rest on the Harbour bed, emptied of water, sealed and then locked to its adjoining sections. The underwater sections of the tunnel were connected in March 1991. The first official crossing was made by the Governor of NSW, Rear-Admiral Sinclair and 17 year old apprentice carpenter Charles Nott on 31st March 1991. It was opened to road traffic in August 1992.