Would you recommend using liquid electrical tape on tricky connections and terminations, or is heat shrink the better way to go?

A: Tend to think that if an installation is so tricky there’s not room for heat shrink then it was poorly planned and executed in the first place. Typically, you’d avoid mid-run connections but if you need them only heat shrink will protect and add physical strength.

Properly done, heat shrink bonds to cable jackets on either side of a butt connection and must be cut out of a cable run. The best way to handle terminations is to crimp the cable into male spade terminals, fork terminals or ring terminals and shrink if required, not unload a glob of liquid electrical tape onto a cable end.

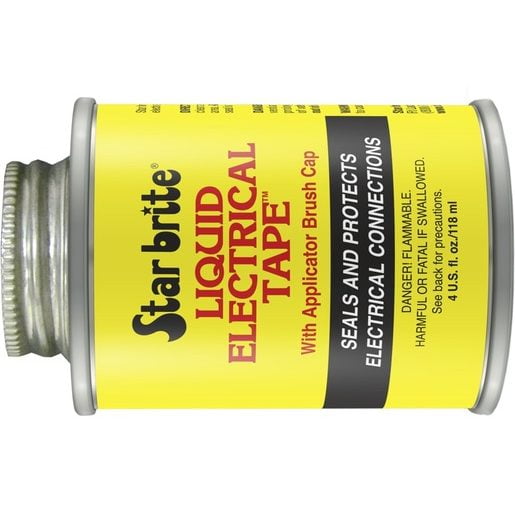

We used liquid electrical tape recently to cover a bare wire connection to a pressure terminal on an alligator clamp. The results were better than electrical tape and might suffice if the connection was never moved or subjected to vibration in the course of its life.

In this case, regular movement broke all wires in the connection and the entire job needed to be redone with a male spade connector heat shrunk to the conductor and the spade in the pressure terminal shrunk to the clamp.

#securityelectronicsandnetworks.com